General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

60 Years Of Rollforming Excellence

Tom Hayes launched Hayes International in 1960 with the motto “We make anything.” We built our first Rollforming machine in 1965, and never looked back. Since that moment, we’ve upheld Tom’s passion and ambition, building a business and community that shares his values.

How It All Started

After Tom left school he worked in a bakery, fish and chip shop, for a boat maker, and helped out a motor mechanic. At 17 Tom decided he wanted a motorcar and so he started collecting parts – axles, springs, a body, chassis, and a radiator. 6 months later, Tom had built himself a motorcar at a total cost of 6 weeks' wages, £6. The car was nice but after a year, Tom saw greater potential in owning a truck. So back to the garage he went! Bigger back axle, wheels and more, and Tom had his truck. Tom managed to secure a fencing contract in a new housing village in Minginui that proved very profitable.

12 Months Later

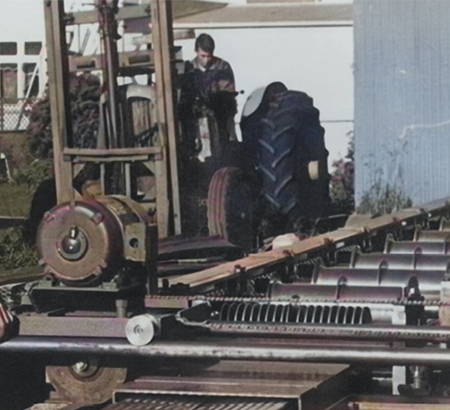

12 months later, Tom returned to Rotorua, operating machinery in a timber yard. While working there, he developed and used his new system laying timber flooring for houses called the End Matcher, saving 25% in costs by using the new tongue and groove system instead of nailing over joists. Tom rented a spare shed from the timber yard and started his own manufacturing and repair business. The beginnings of Hayes International was born, and with it, the motto “We make anything”. And back in those days, we did! Forklifts, sawmills, log handling equipment, conveyor systems, and even parking meter straighteners! Along the way, we were asked to make a Rollformer.

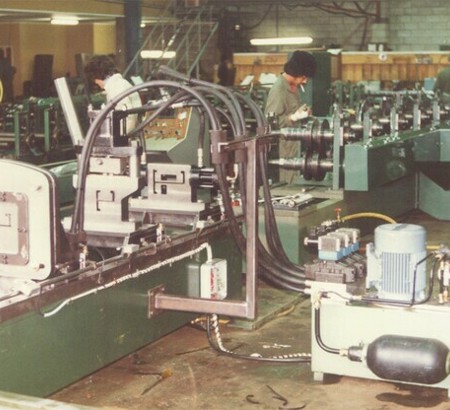

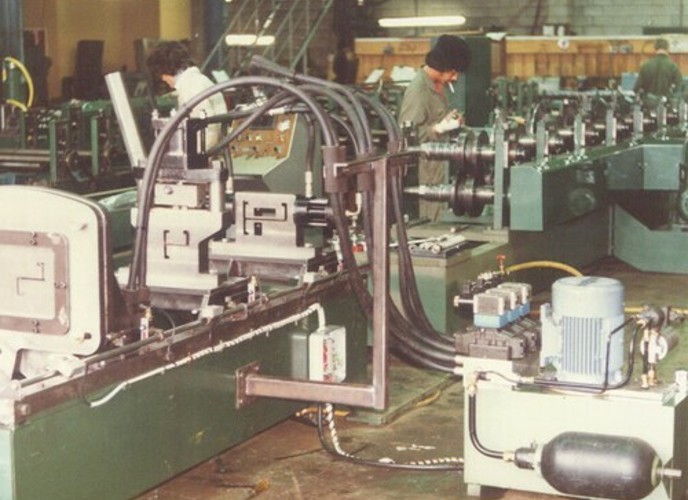

Hayes International's First Rollformer

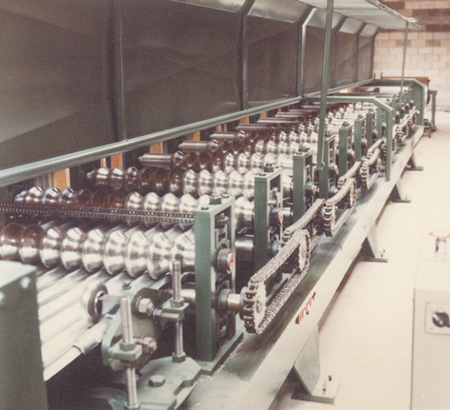

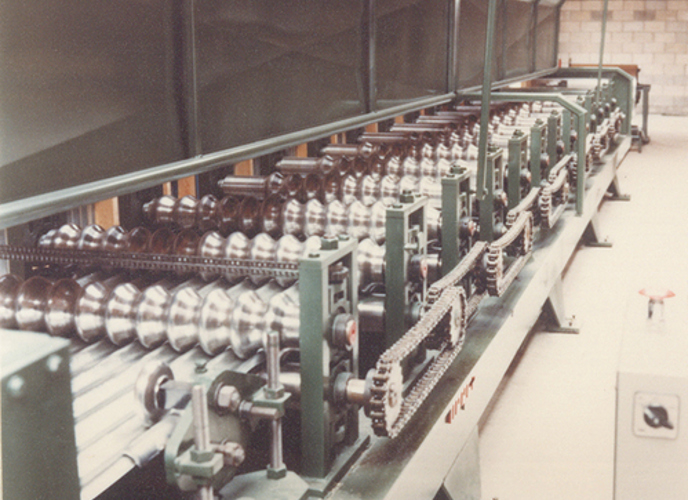

Rollformers are machines that take a flat metal usually steel coil and run it through a series of rotating forming stations to form a profile. The steel is then cut to length to produce the finished product. Corrugated iron is the most easily recognized product produced by Rollforming.

The Bradbury Group

In July 1999, Tom Hayes sold Hayes International to the Bradbury Group. The Bradbury group is a corporation based in Kansas USA that started in 1959 and began by operating a roll-formed products division and by manufacturing roll tooling for customers involved in metal forming. Today, the Bradbury Group consists of The Bradbury Co., American Machine & Rollform tech, Beck Automation LLC., Hayes International, Marion Die & Fixture, Custom Rollforming Corp., Bradbury U.K., Bradbury Group Australia, Metform International Ltd., Alliance Machine & Engraving LLC, Athader S.L., Bradbury Group Pu.Ma., And Bradbury Metal Tile Roofing Solutions. To extend its international reach, Group sales offices also include Bradbury Russia, Bradbury India, Bradbury Mexico as well as agents worldwide.

Hayes International

Today, Hayes International manufactures Rollformers and associated metalworking equipment. 95% of our product is exported and sold to over 90 countries around the world.