Hayes International, located in Rotorua, New Zealand and part of The Bradbury Group, offers high-quality Panel roll formers that can be equipped with a Flying Post-Cut system with an all-electrical shear. This cutting-edge line has the capability to produce twenty 10ft panels per minute. With precision engineering and cutting-edge technology, Hayes International is at the top of the industry when it comes to efficiency and quality in panel production.

Key Features and Advantages

The Hayes Coil Car provides a safe and efficient way to load coils onto the decoiler, reducing the risk of edge damage or imperfections on the surface. This innovative solution not only protects the material but also enhances the overall quality of the final product.

The Hayes Double End Uncoiler increases panel production by allowing continuous operation while the next coil is loaded onto the offline mandrel. These uncoilers utilize electric drives, ensuring quiet operation and precise control over decoiling speeds.

The laser loop sensor provides a non-contact way to monitor the loop and control the speed of the uncoiler. This eliminates the need for a mechanical loop arm riding on the surface of the material.

The material guides on the Hayes roll former are designed with high-quality bearings that guide the edge of the material to prevent scratching and edge damage to the coil, which can lead to defective panels.

The electric entry shear offers an efficient solution for postcut panel lines by automatically shearing the last panel of the batch or order, eliminating waste.

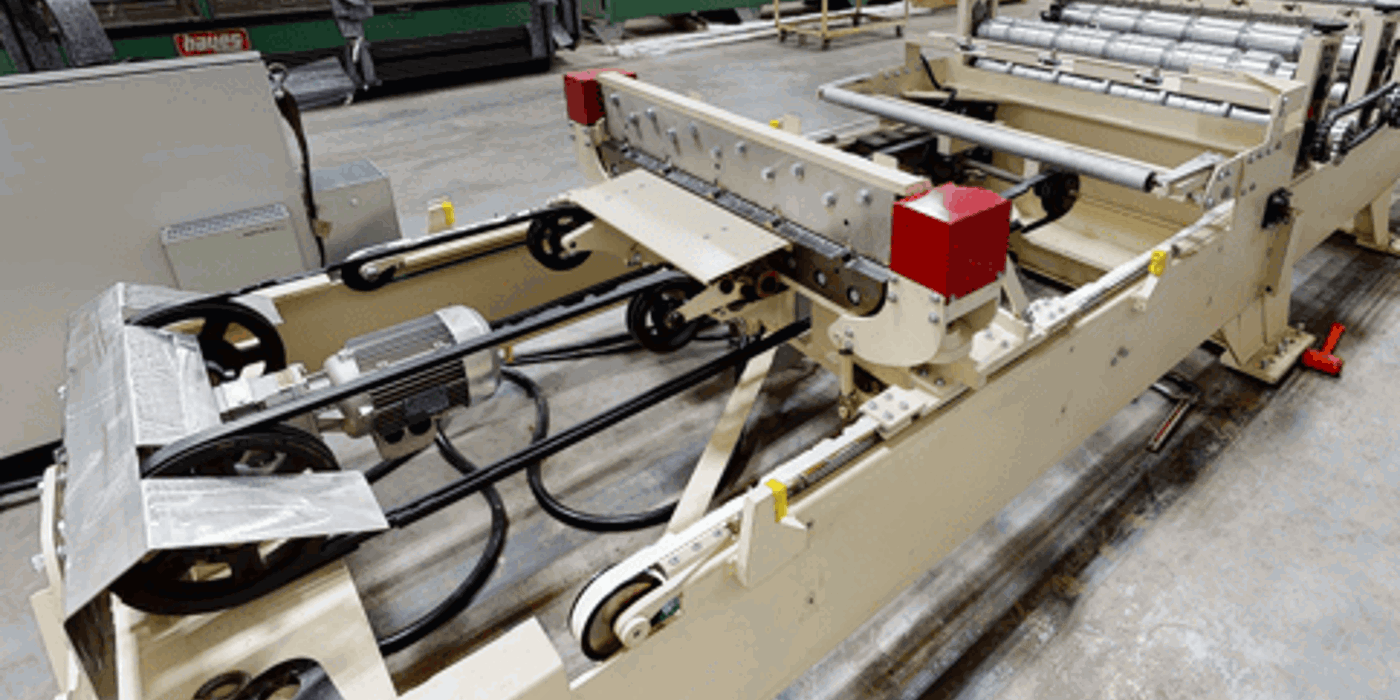

Hayes Post Cut ShearHayes roll formers come equipped with a single-point adjustment feature on the major overform passes. This feature is utilized to adjust the roll tooling and maintain panel shape effected by varying tensile strengths and steel thickness, while ensuring that the tooling remains parallel.

The Post-Cut Flying Shear feature at Hayes revolutionizes panel production at 200 FPM throughput, no minimum length requirement, minimal end flare, and a simulated upcut shear that produces an upwards burr to prevent scratching when stacked.

With these advanced features, Hayes sets itself apart as a leader in the industry, providing versatile solutions for a wide range of panel production needs.

If you're in the market for a panel roll forming line, be sure to explore the offerings at Hayes International. Feel free to reach out to us and finding out how we can tailor a roll forming line to meet your specific needs. We look forward to visiting with you about designing your next innovative solution in panel production.