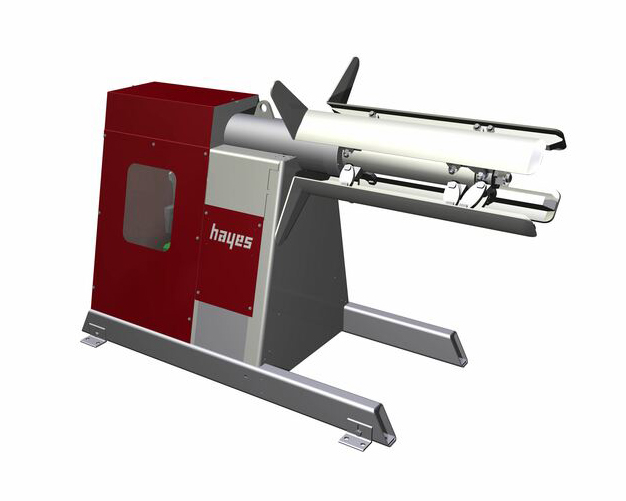

Custom Metal Industries is a 4th generation family business based out of Greenfield Indiana and has used Bradbury Group and Hayes Machines since 1960. Custom Metal Industries and Hayes have grown together, in a true partnership lasting for generations.

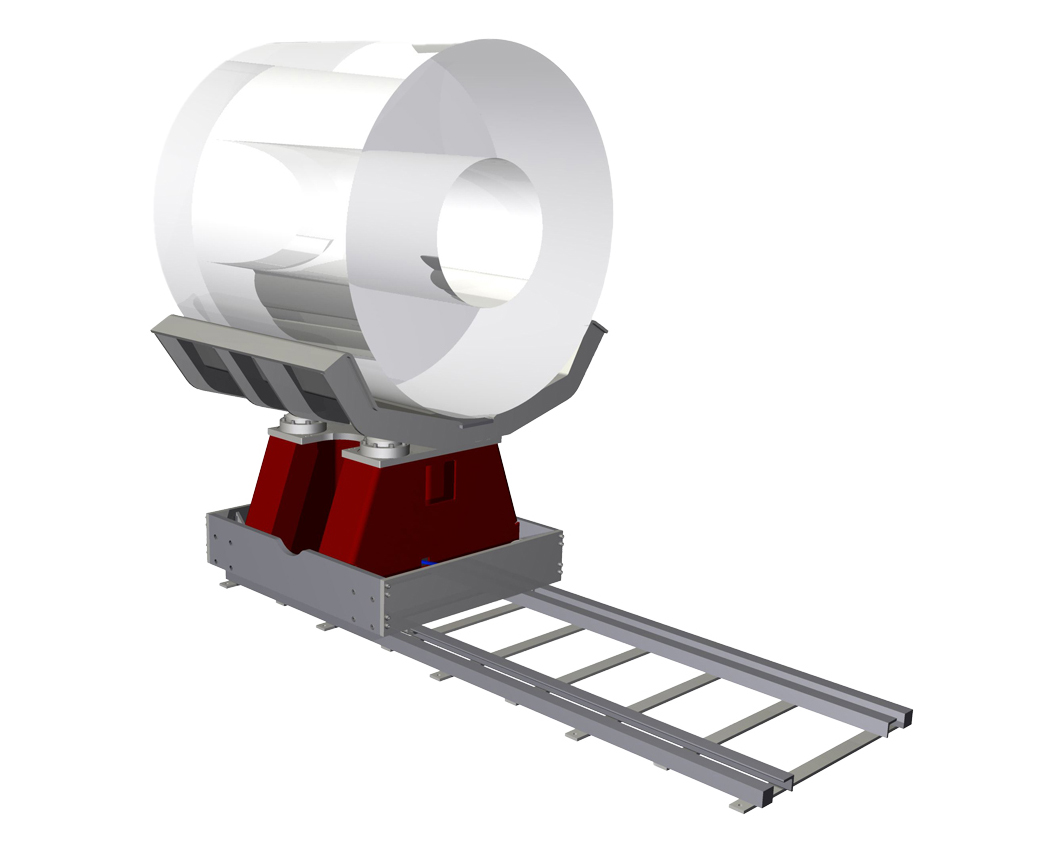

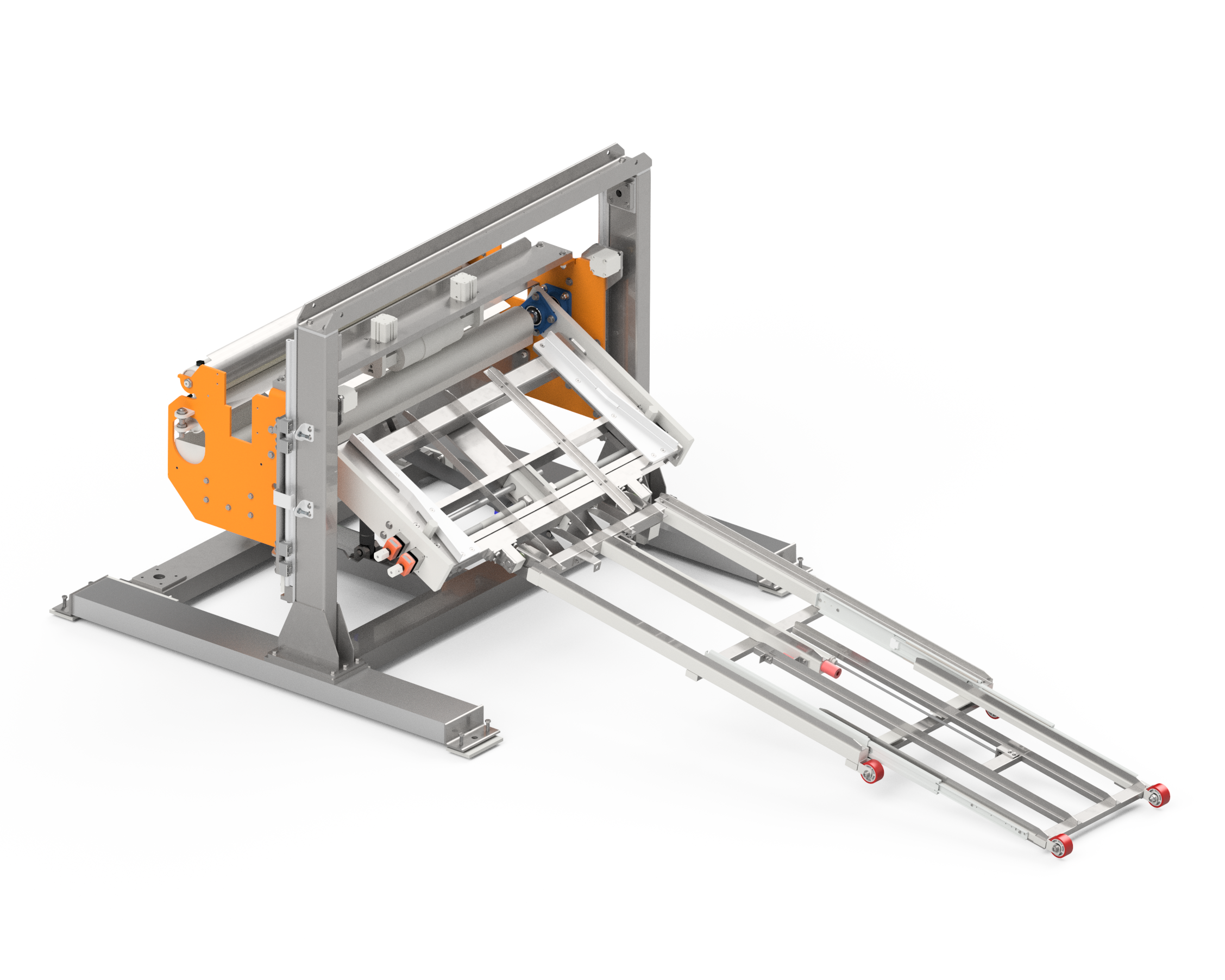

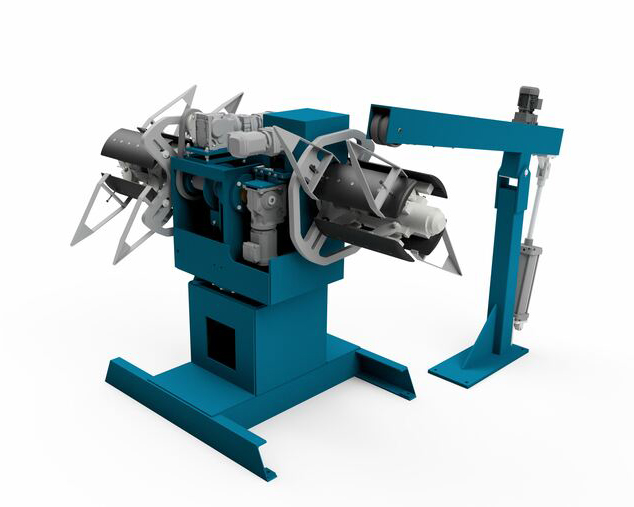

Linkage Uncoiler Standard Components Details

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.