General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

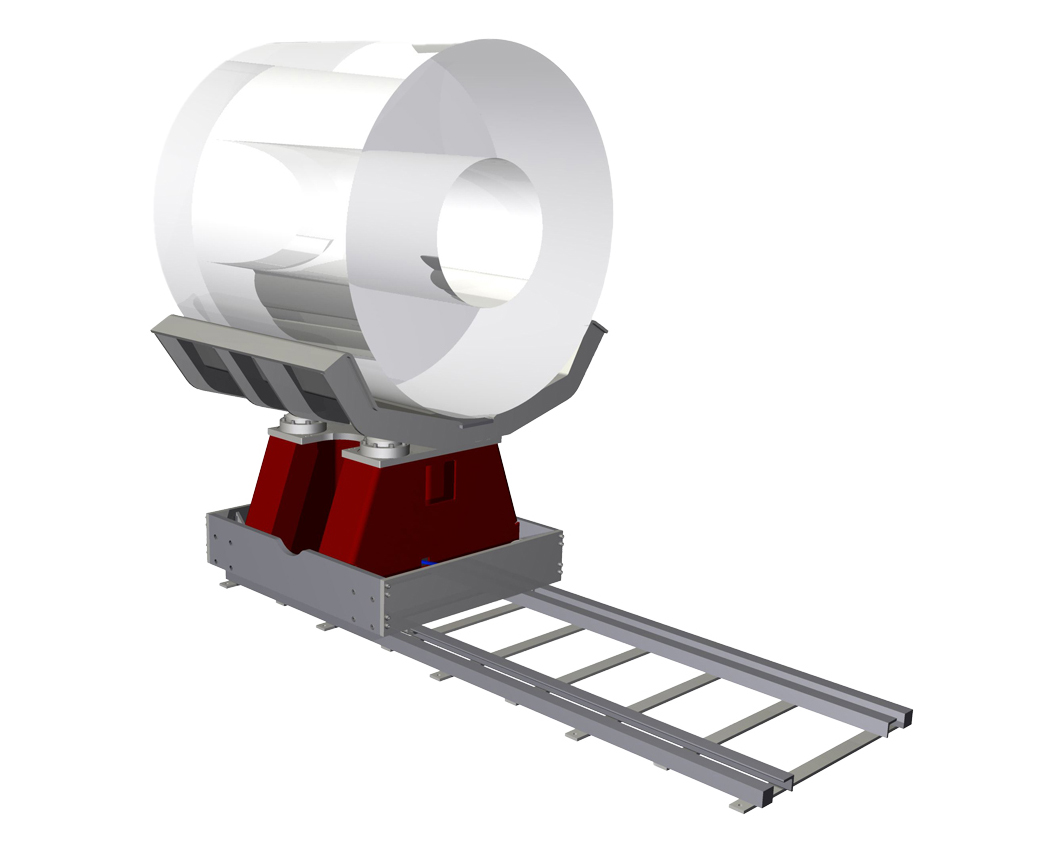

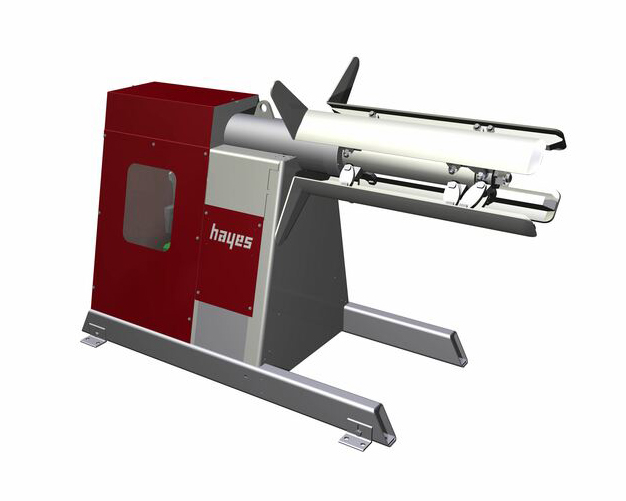

Twin Mandrel Uncoiler

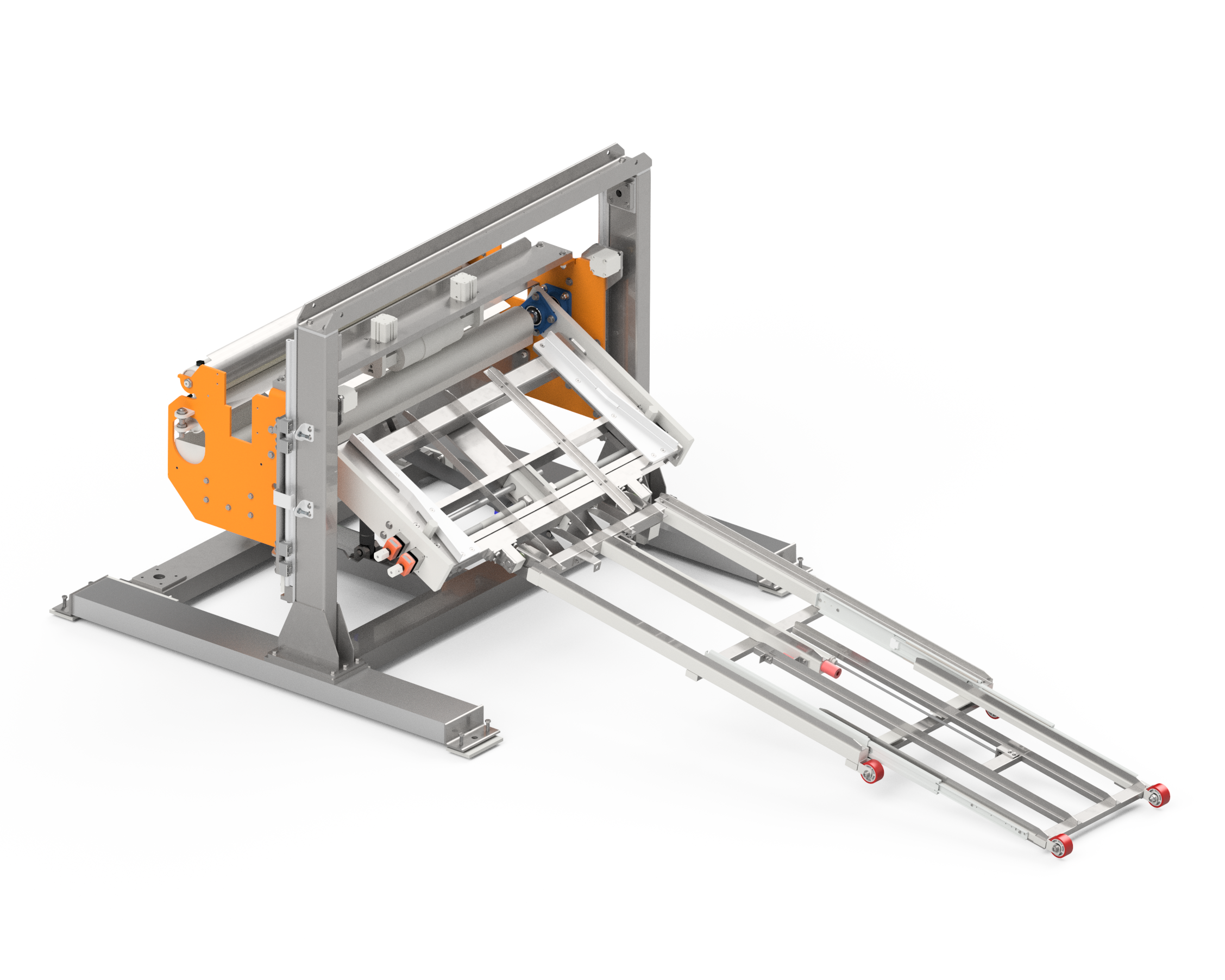

The Hayes Twin Mandrel Uncoiler is a fast and efficient way to change between materials for different orders or minimize the time it takes to feed up a new coil. It keeps production going, saving time and increasing productivity, especially when paired with a Hayes Coil Car, which allows for efficient loading of new coils.

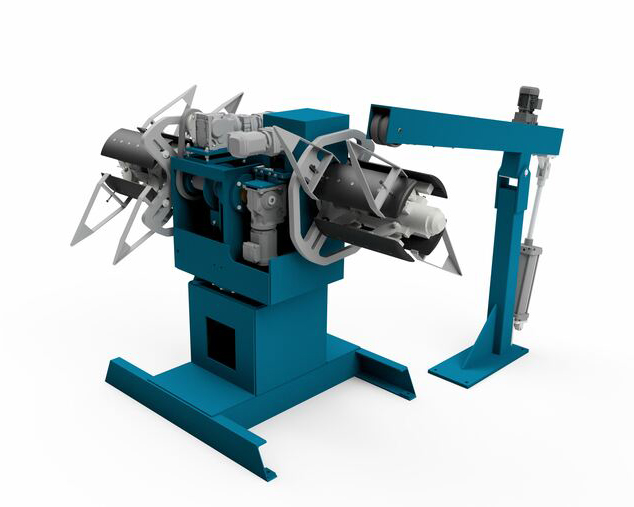

A typical Twin Mandrel Uncoiler has a capacity of 6 tonnes per side. Both mandrels are attached to a rotating turret coupled to the cooler base via a heavy-duty bearing and driven with an internal sprocket and VFD Electric motor, allowing for full 360° rotation. The cooler mandrels are a 4-leaf assembly available in both wedge and linkage expansion configurations, depending on the desired application.

A standalone operator console with a touch screen is used to operate the Uncoiler in tandem with a Rollforming machine.

ENQUIRE NOW

Twin Mandrel Uncoiler Standard Components Details

- Welded steel construction painted with lacquer finish.

- Removable guarding covering the main drive and pinch points.

- Four solid steel palm plates are attached to the mandrel shaft via steel linkage assembly or captive wedges, depending on the application.

- Expand/retract controlled via hydraulic piston and onboard self-contained power pack.

- Pressure-reducing valve minimizes potential damage to coil bore.

- Rotational power is provided to each mandrel via a dedicated VFD electric gearmotor coupled via heavy-duty chain and sprocket transmission.

- Variable payoff speed controlled via overhead laser.

- Can run in reverse -in combination with a snubber arm- to allow for the re-winding of coils.

- Rotation of turret for changing between online/offline coils achieved via internal sprocket and VFD electric motor capable of full 360° operation.

Hayes Twin Capstan Uncoilers are available in multiple configurations including 1250mm wide mandrels for wider coils and narrow versions for use with purlin coils. Please contact Hayes International for more information on an uncoiler to suit your needs.

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.