General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

Dual Level Rollformer Standard Components Details

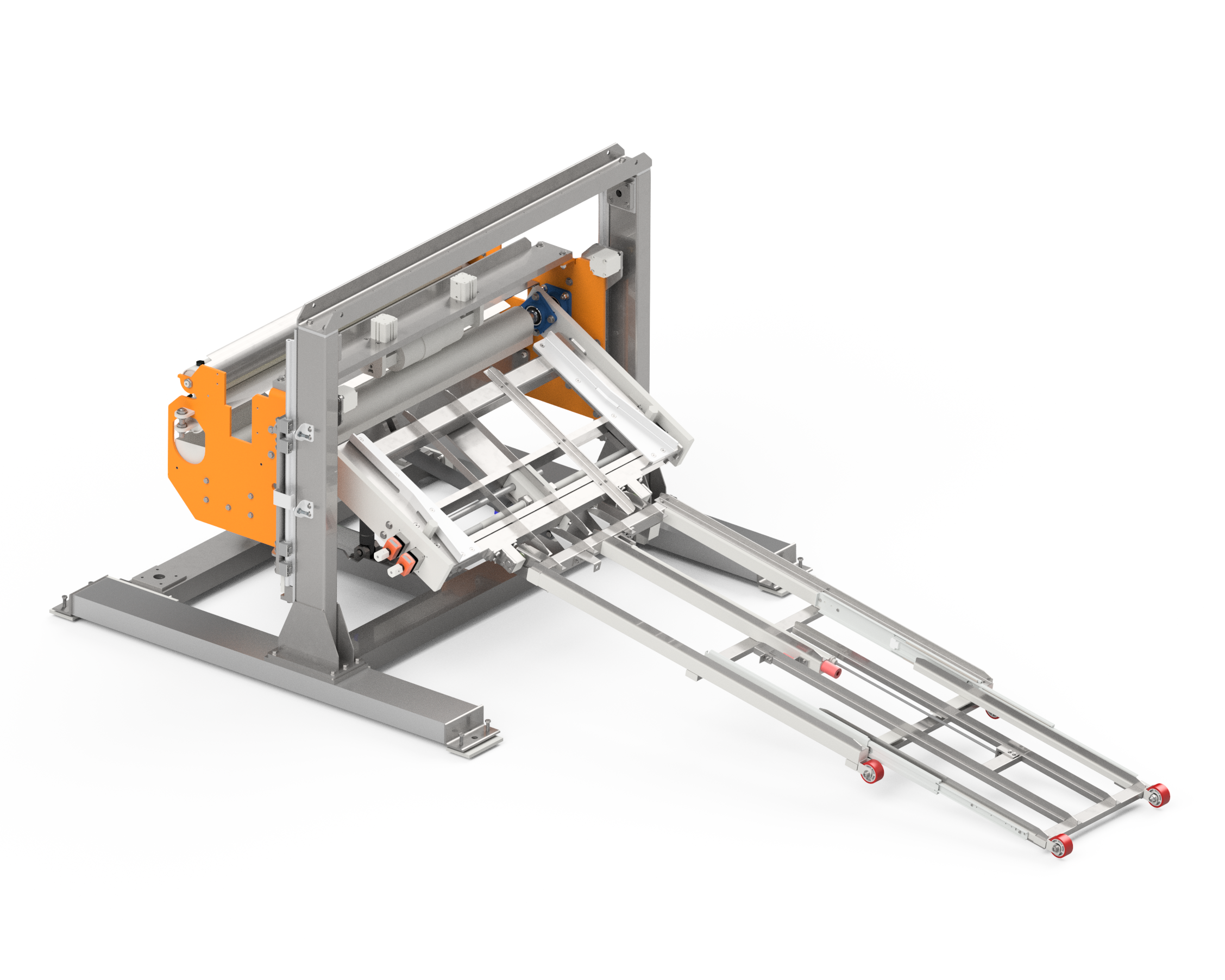

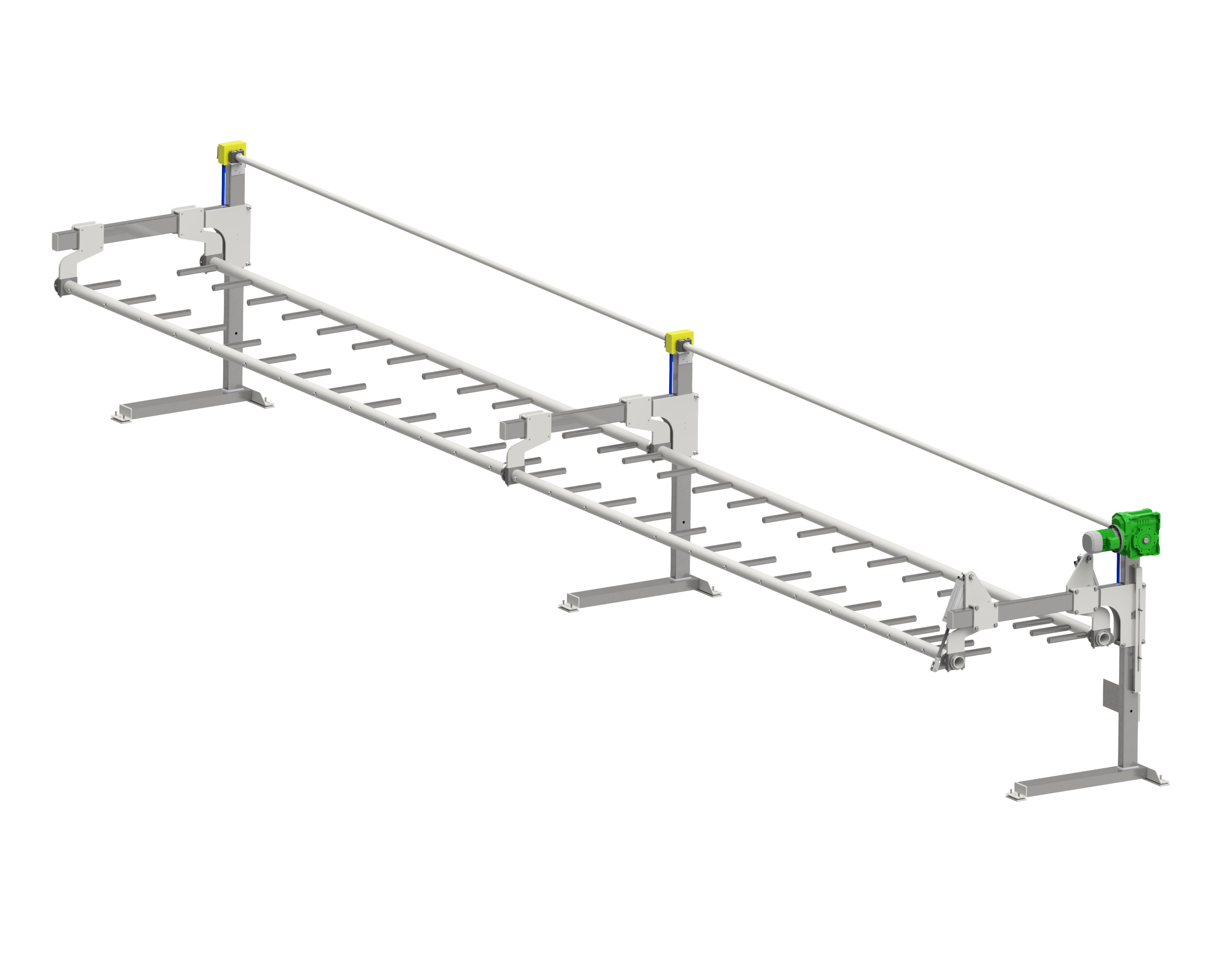

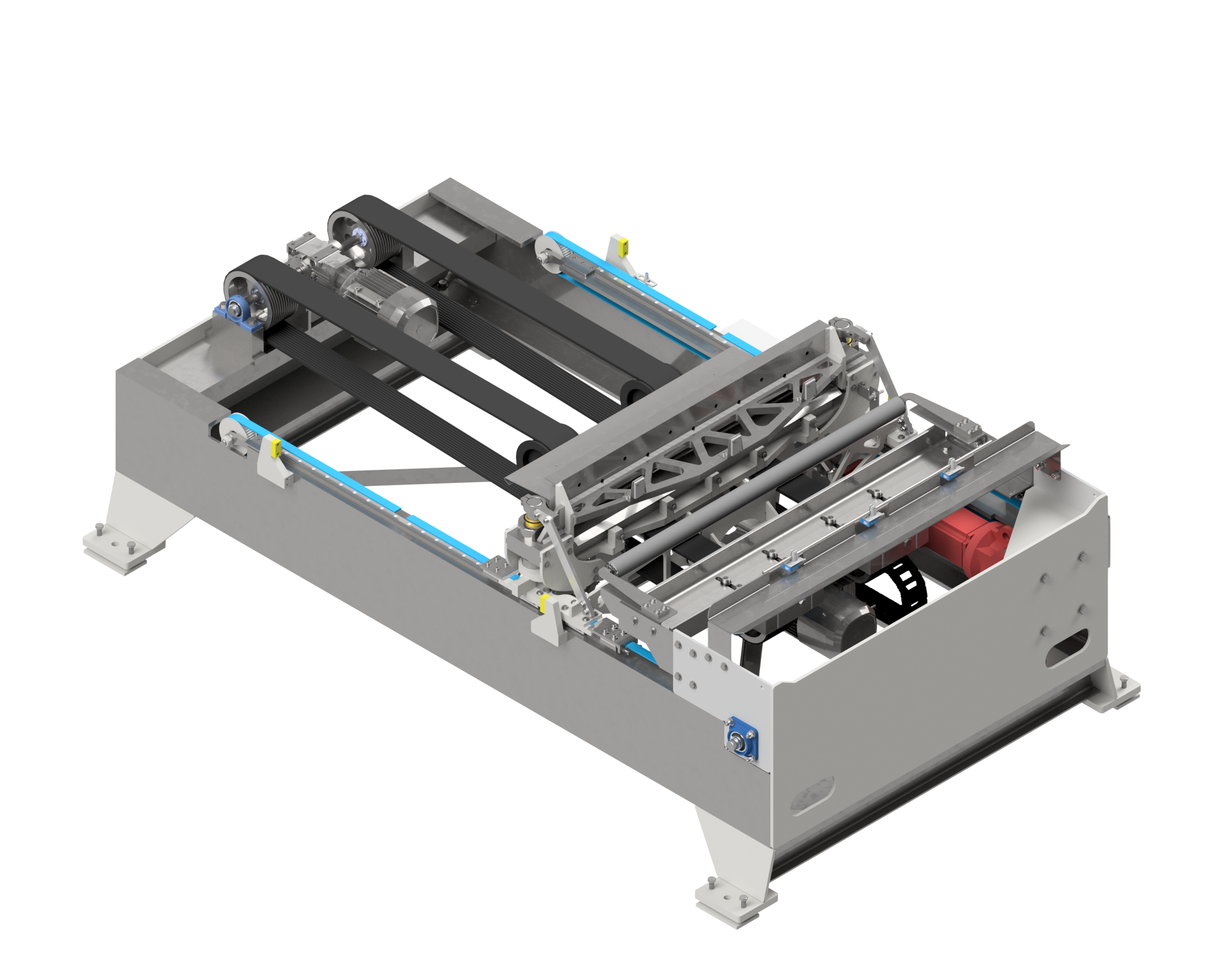

- Two sets of tooling with staggered pedestals allow for multiple profiles in the same footprint as a Hayes Single Level Rollformer.

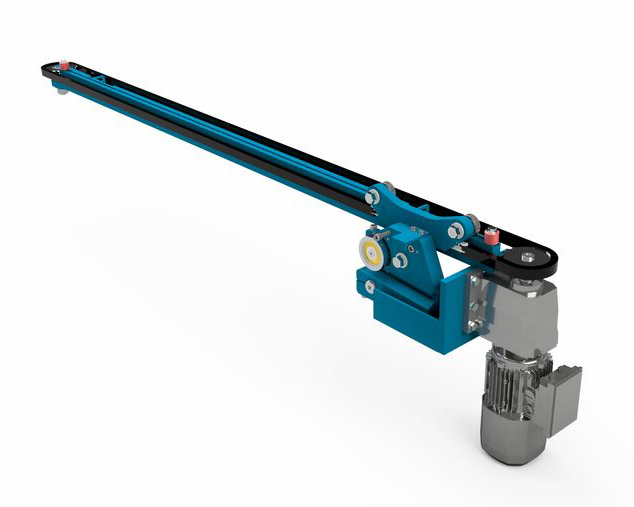

- Each toolset is driven independently via a dedicated electric gear motor.

- Dual level adjustable infeed guides to suit coil discrepancies and control under/overlap length; positioned via Siko type screw adjustment.

- Dual level built-in lubrication system with felt wick applicator that applies lubricant to both sides of the sheet.

- Manual pull-across slitter or a powered slitter with D2 hardened steel knives to reduce waste material.

- Fabricated steel chassis in segments for easy handling, painted with a lacquer finish.

- Reference marking and leveling feet for ease of alignment.

- Pedestals are a heavy-duty welded steel design with all working surfaces precision machined. Pedestals are height offset to allow one profile to run above another.

- Each pedestal houses heavy-duty self-aligning bearings with tooling shaft locking collars.

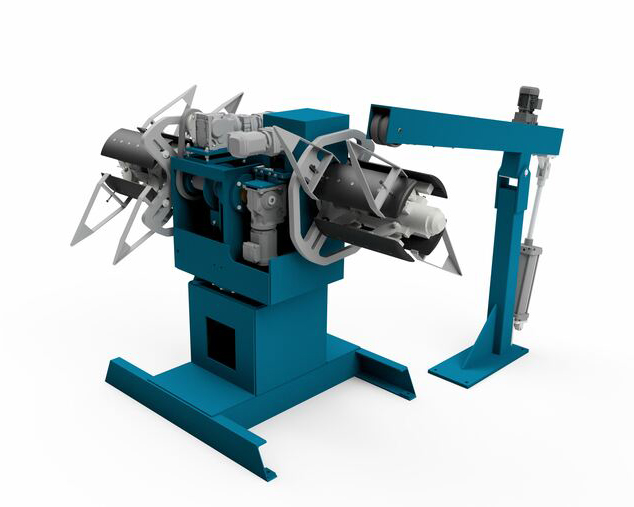

- Multiple tooling options are available depending on the profile spec and the line speed required. All options are precision CNC machined in house. These include:

- Solid K1045 steel tooling rolls with a hard chrome finish.

- Segmented D2 Steel through hardened to KC60 grade.

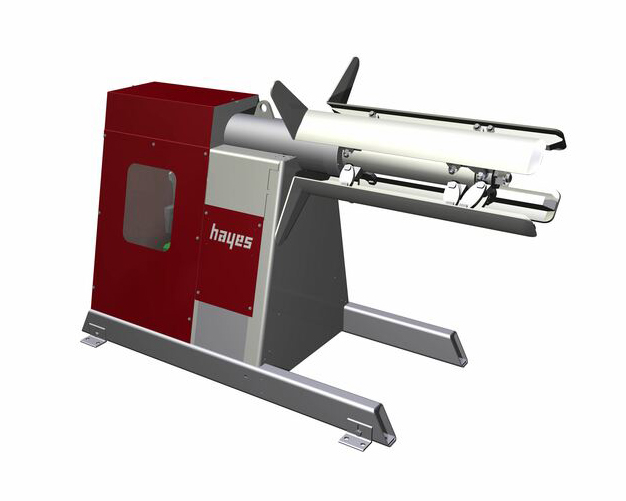

- Driven by dedicated VFD Electric motors mounted inside the chassis with each toolset individually driven.

- Power transmitted via heavy duty chain and sprocket.

- Secured via Bonfix style couplings.

- Each bottom roll of tooling is driven, with the first stations coupled via spur gear to aid traction.

- Guarding covers tooling rolls and transmission.

- Welded steel and mesh construction painted with lacquer finish.

- 2 Configurations available: 'Lift up' guards that open upwards with the aid of gas struts, or interlocking tunnel guards that open via sliding on track and rail system.

- All guards are equipped with interlocking safety switches integrated into the safety system.

- Polycarbonate guarding option available.

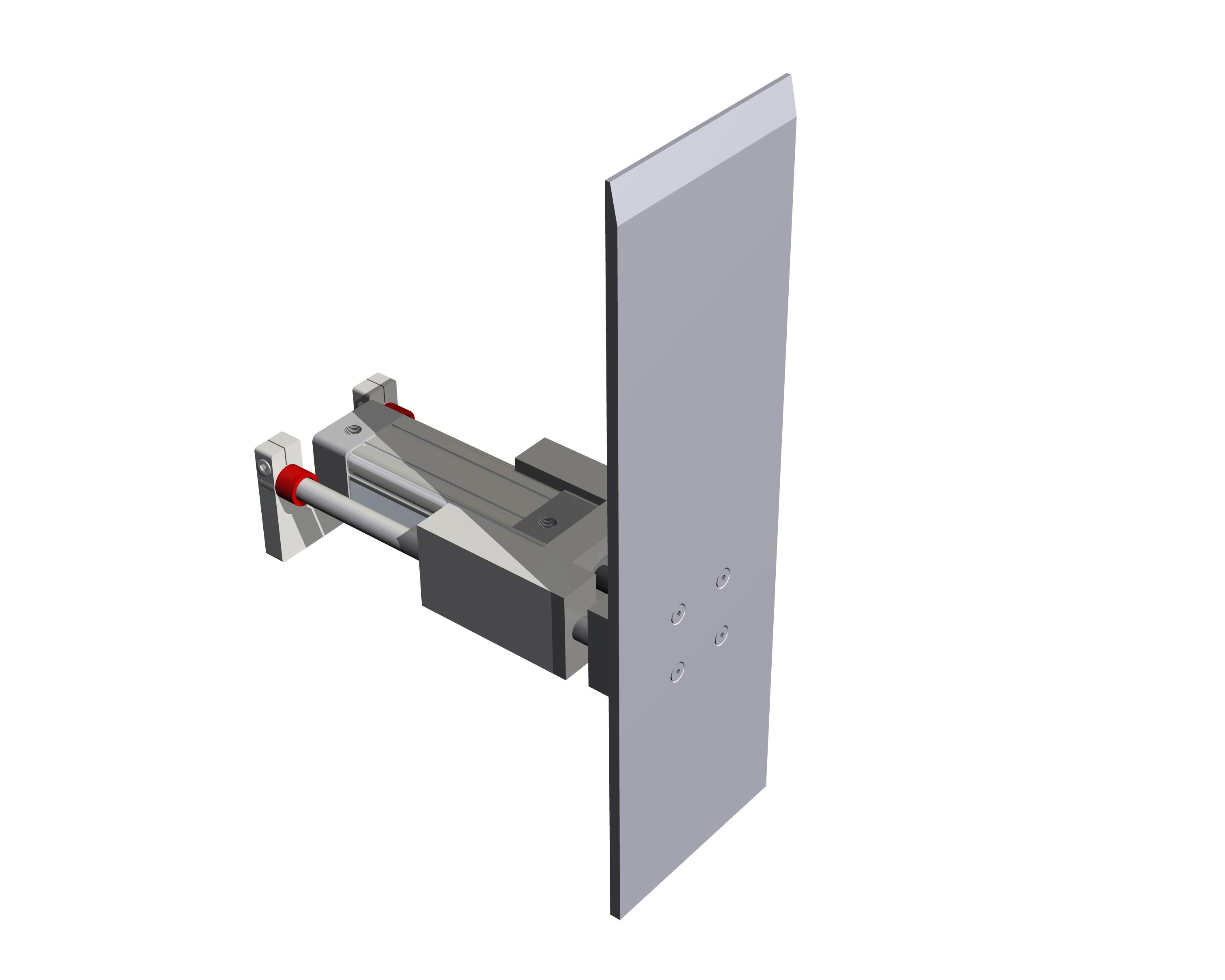

- Heavy-duty twin pillar post-cut guillotine with dual-level operation.

- Hydraulically operated via a dedicated power pack housed inside the chassis.

- Replaceable D2 through-hardened steel blades precision that are ground and sharpened.

- Dedicated operator's console controlled via a PC and Hayes SmartCut multi-batching control.

- Fully instrumented controls capable of operating in manual or automatic modes.

- Data download and order entry facilities, fault-finding capability and operating safety system.

- Can be configured to run select 3rd party control systems.

- ERP integration capability (subject to controller type) with production reporting, scrap monitoring, etc.

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.