General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

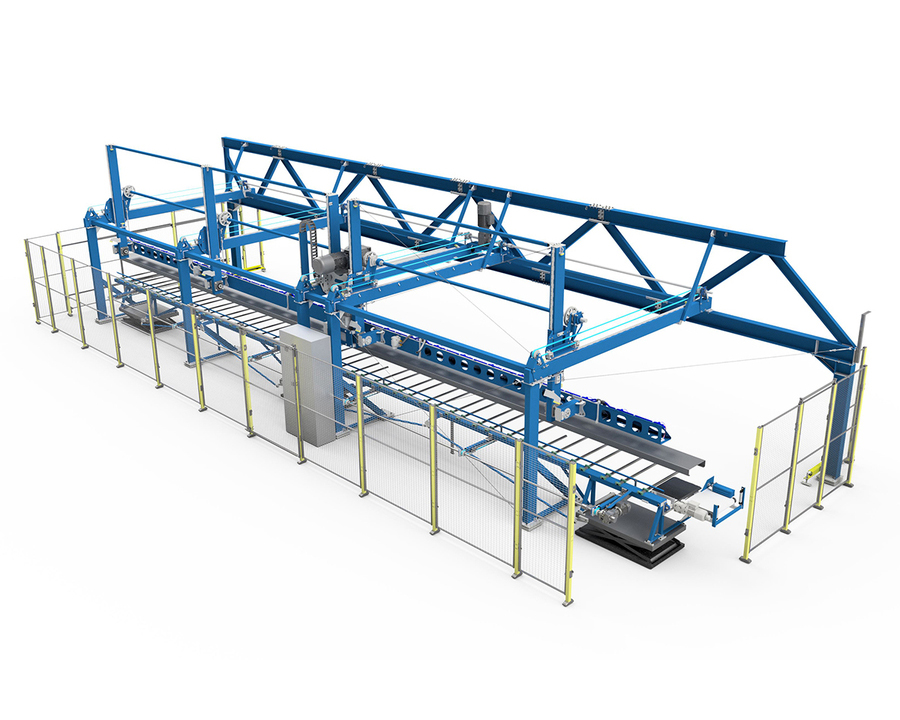

Purlin Stacker

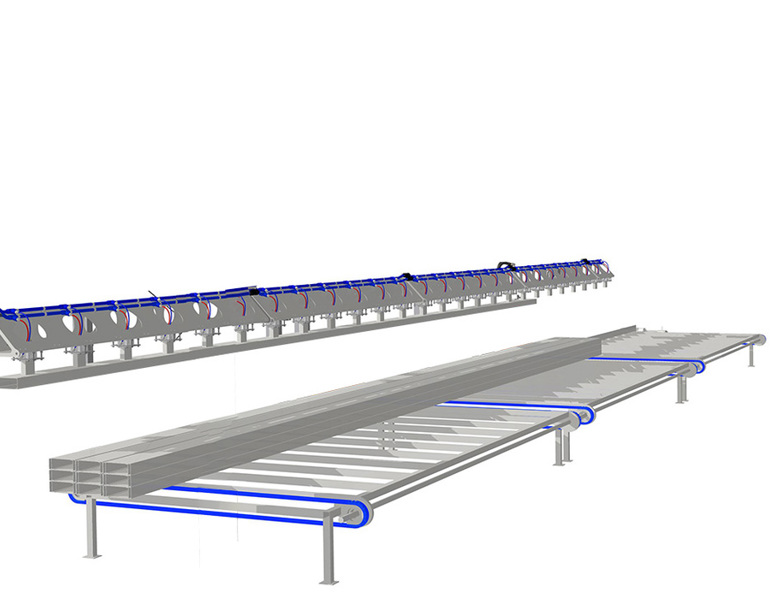

Hayes Purlin Stacker systems enable a seamless, hands-free stacking operation from the exit of the purlin machine.

The Hayes Purlin Stacker stacks finished profiles via mechanical push and flip / nest technology to present finished products neatly and ready for strapping, either manual or automatic.

The Hayes Purlin Stacker is fully fenced unit with guarding around the entire perimeter and light curtains placed at the collection side of the stacker to prevent danger to operators.

Details:

100 – 400 mm in size

16 – 25 meters in length

Cee, Zed, and plain channel capable

Custom sizes available on request

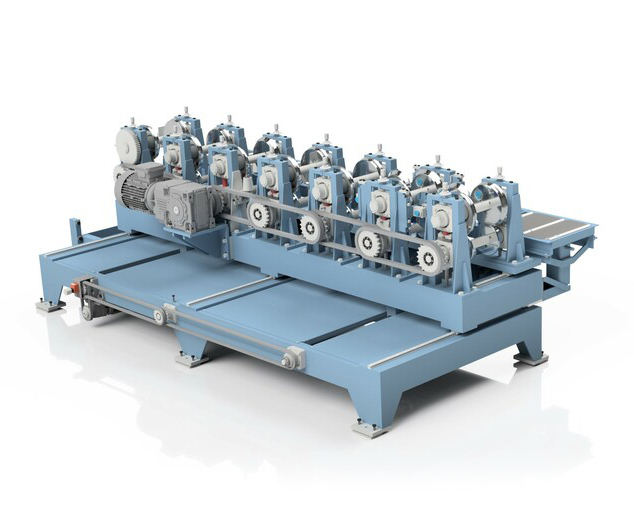

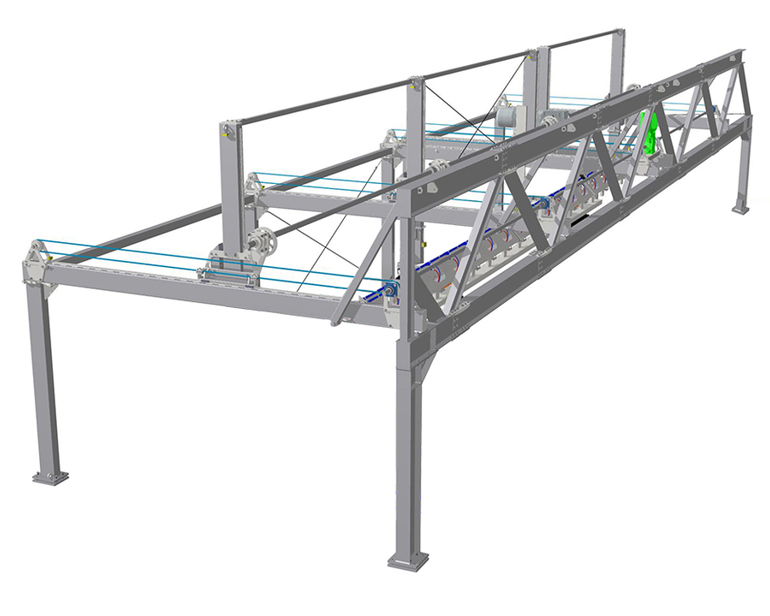

Purlin Stacker Standard Components

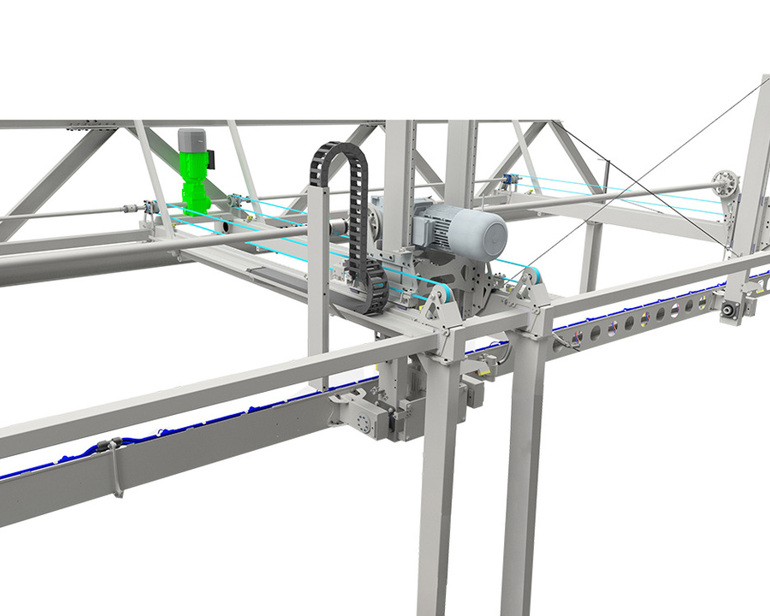

- Heavy-duty steel frame and truss design painted with lacquer finish.

- 3 C-frame supports are designed to absorb stress and shock from picking and placing of the product.

- The steel frame and truss design leaves one side of the stacker clear of vertical beams to allow for safe offloading of complete bundles.

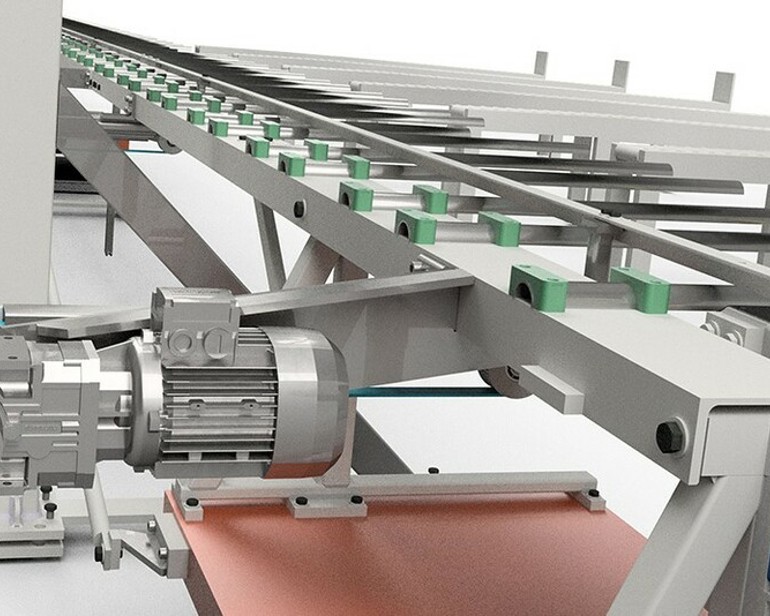

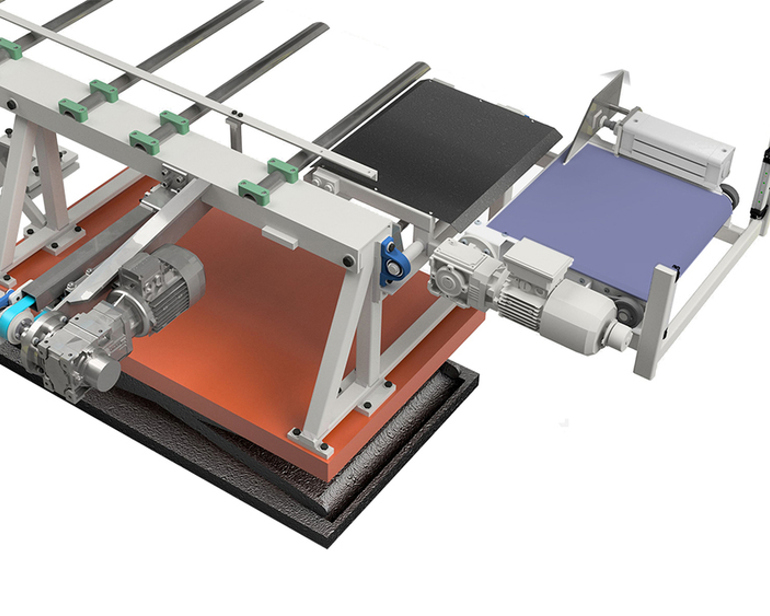

- Exit table with drive out conveyor.

- Height adjustable to allow for differing flange heights and profiles.

- Pusher arm and tamper arm used to move purlin to 2 known datum points for accurate alignment.

- Pusher arm mounted lengthways along the exit table pushes purlin flush, and clear of the exit table to allow a second purlin to pass behind whilst the first is moved by the articulating arm.

- Tamper is positioned at the drive-out conveyor to push the purlin end flush.

- The articulated arm split into 3 segments spans the entire length of the stacker.

- The Stacker head utilizes pneumatically operated permanent magnets that raise/lower into place to magnetically hold the purlin profile.

- Permanent magnets eliminate the risk of dropping a purlin due to loss of power or pneumatics.

- Stacker head can rotate 180 degrees to position purlins in neat and tidy bundles.

- Positions Purlins in a safe position outside the stacker once the bundle is complete.

- A transverse chain drive is used to position purlin bundles powered via multiple VFD Electric motors.

- Light curtain mounted parallel to fencing that allows only purlin bundles to pass through unobstructed.

- Dedicated standalone operator's console with LCD display.

- Specialized Hayes software communicates with Rollformer software to manage purlin and bundle size. Once coupled to the main Rollformer software, the stacker acts as the 'slave' while the Rollformer is the 'master' and controls the main functions.

- Designed to run automatically with minimal operator intervention.

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.