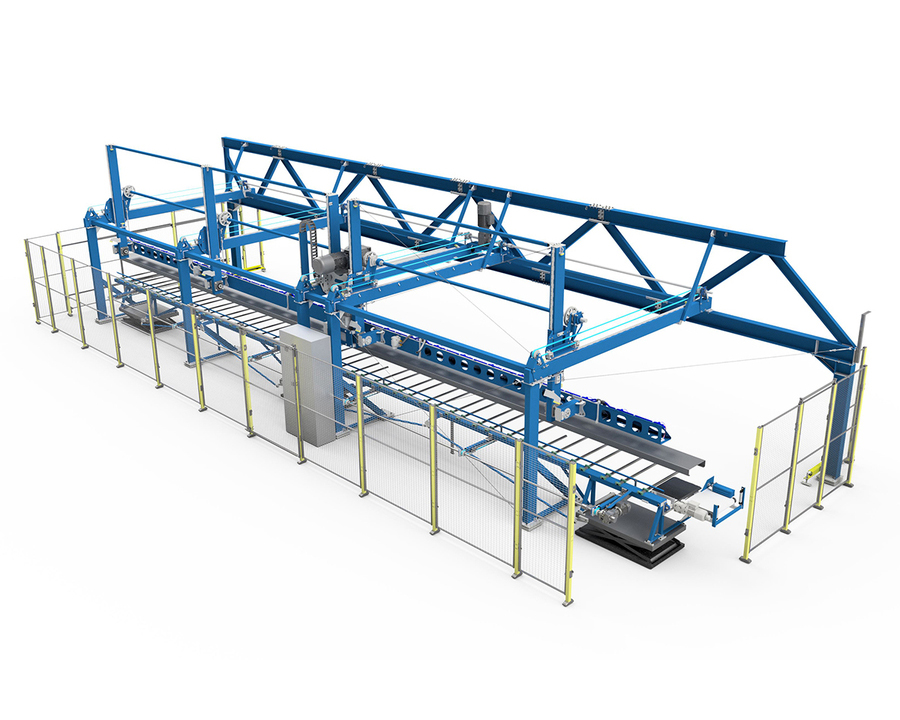

General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

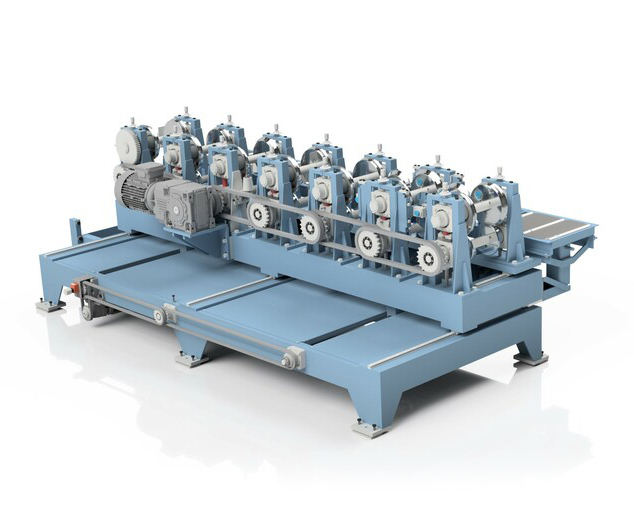

Sigma Purlin Section

The Sigma Purlin Section is an additional set of tooling that can be ordered with Hayes Purlin Mills.

Fabricated with the same welded steel design and D2 through hardened tooling rolls as all Hayes machines, the Sigma tooling section is positioned at the exit end of the machine.

The entire tooling section is mounted on a sliding raft assembly that can be moved out of position in exchange for a conveyor section to allow other profiles to bypass the sigma section when required.

The raft positioning is controlled via an electric gear motor, and the screw drive is controlled by the operator; the forming stations are driven by a dedicated electric gear motor.

ENQUIRE NOW

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.