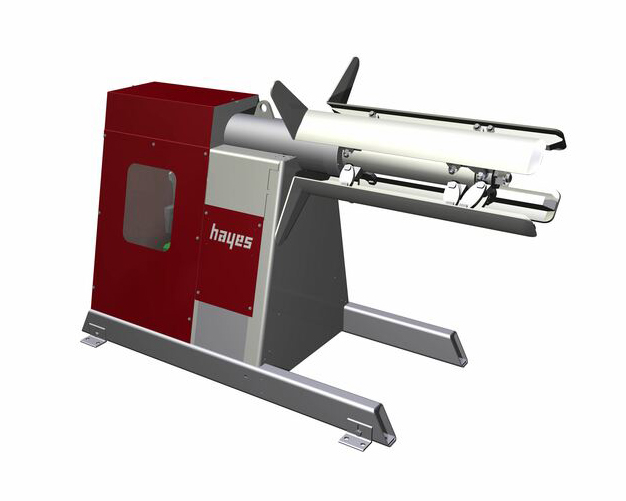

General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

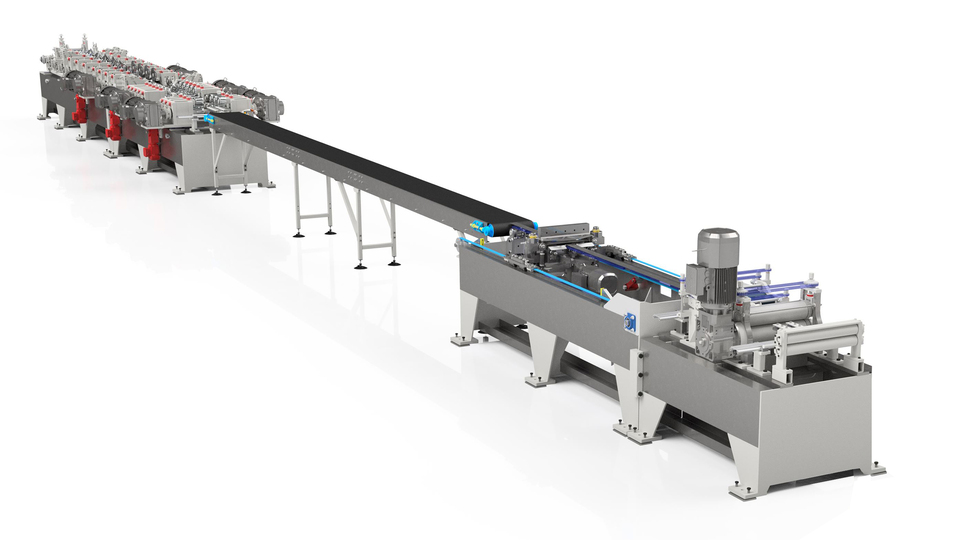

Stud Mill Standard Components Details

- Adjustable Vee-throated infeed guides to suit coil discrepancies positioned via Siko-type screw adjustment.

- Dual pinch feed rolls machined from hardened 4340 steel rolls spur gear coupled and fitted with chain-coupled pressure screws to adjust traction.

- Straightening rolls to remove 'Coil set'.

- Recycling spray lubricator applies lubricant to both sides of the strip before forming.

- Fabricated steel chassis manufactured in segments for ease of handling and painted with a lacquer finish.

- Reference marking and leveling feet for ease of alignment.

- Pedestals are prefabricated welded steel designs with precision machined working surfaces.

- Pedestals adjustable via powered raft for web and channel adjustment.

- Hydraulically powered via a dedicated power pack.

- Static shear for trimming strip lengths and interchangeable part-cut die that leaves a small amount of material between profiles that can be easily snapped for lengths below 1750mm.

- Dynamic punch heads positioned on moveable rafts of adjusting hole position. Punch head amount is configurable dependent on production requirements.

- Solid DS steel tooling rolls are precision-machined and through-hardened to RC60 grade.

- Tooling rolls contain Hayes's patented 'Auto Gauge' system, removing the need to adjust for material thickness.

- The optional embossing pass for 'Glue facing' can be added or removed by sliding in or out of the rotary die.

- Six dedicated AC electric gear motors coupled via chain and sprocket transmission drive the tooling segments.

- Drive motors controlled via VFD for accurate strip positioning and smooth stop-to-cut operation.

- Pinch feed rolls are powered by dedicated motors and coupled via spur gear.

- Fixed height transmission and shear guarding.

- All moveable guards are complete with integrated safety switches.

- Fence guarding can be supplied separately by Hayes once the final factory layout is completed.

- Standalone operator console with PC with graphic display used for order entry and programming.

- Provided with Hayes International proprietary software, fully featured with a user-friendly interface and multiple production-saving features.

- Graphic display shows hole position relationships as well as order progress and status.

- Height-adjustable exit table 11.5-meter length.

- Steel roller supports.

- Lift-up section allows for access to the opposite machine side. The gate is paired with a safety switch that stops the machine when the gate is open.

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.