General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

Crimp Curver

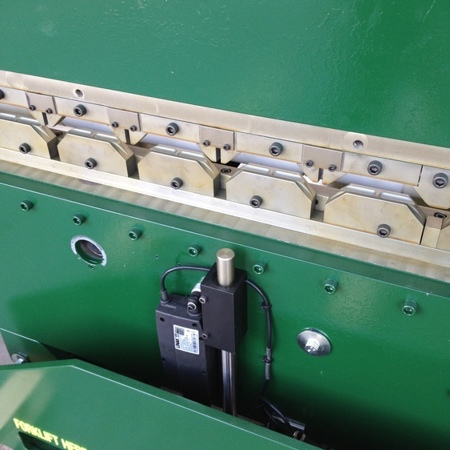

Hayes Crimp Curvers are hydraulically operated presses for the incremental curving of trapezoidal profiles. Each pass of the press imparts a crimp into the sheet, causing it to deflect by a constant angular amount while keeping the material coating intact and undamaged.

Adjusting the spacing between crimps allows for variation of the radius. Die sets are precision machined steel and may be reversed to suit the overlap direction or swapped for a different profile.

ENQUIRE NOW

Crimp Curver Standard Components Details

- Welded steel plate construction painted with lacquer finish.

- The chassis tilts 90° on the base to operate in vertical or horizontal configurations.

- Precision machined die sets made to suit profile.

- Heat treated to D2 hardness.

- Die sets are easily reversed for overlap adjustment or swapped out completely for another profile.

- Welded steel construction.

- Driven via servo motor for accurate spacing of crimps and precise indexing.

- Squaring and positioning stops fitted for initial set-up.

- Heavy-duty construction.

- Hydraulically operated via a dedicated power pack.

- A fully instrumented operator console is mounted to the machine chassis via a pivoting arm.

- Automatic or manual operation is available.

- The touchscreen controller is used to set the curve angle, curve radius, die angle, and pitch.

- The included software will calculate crimp spacing and angle to achieve the required radius based on material specifications and length.

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.