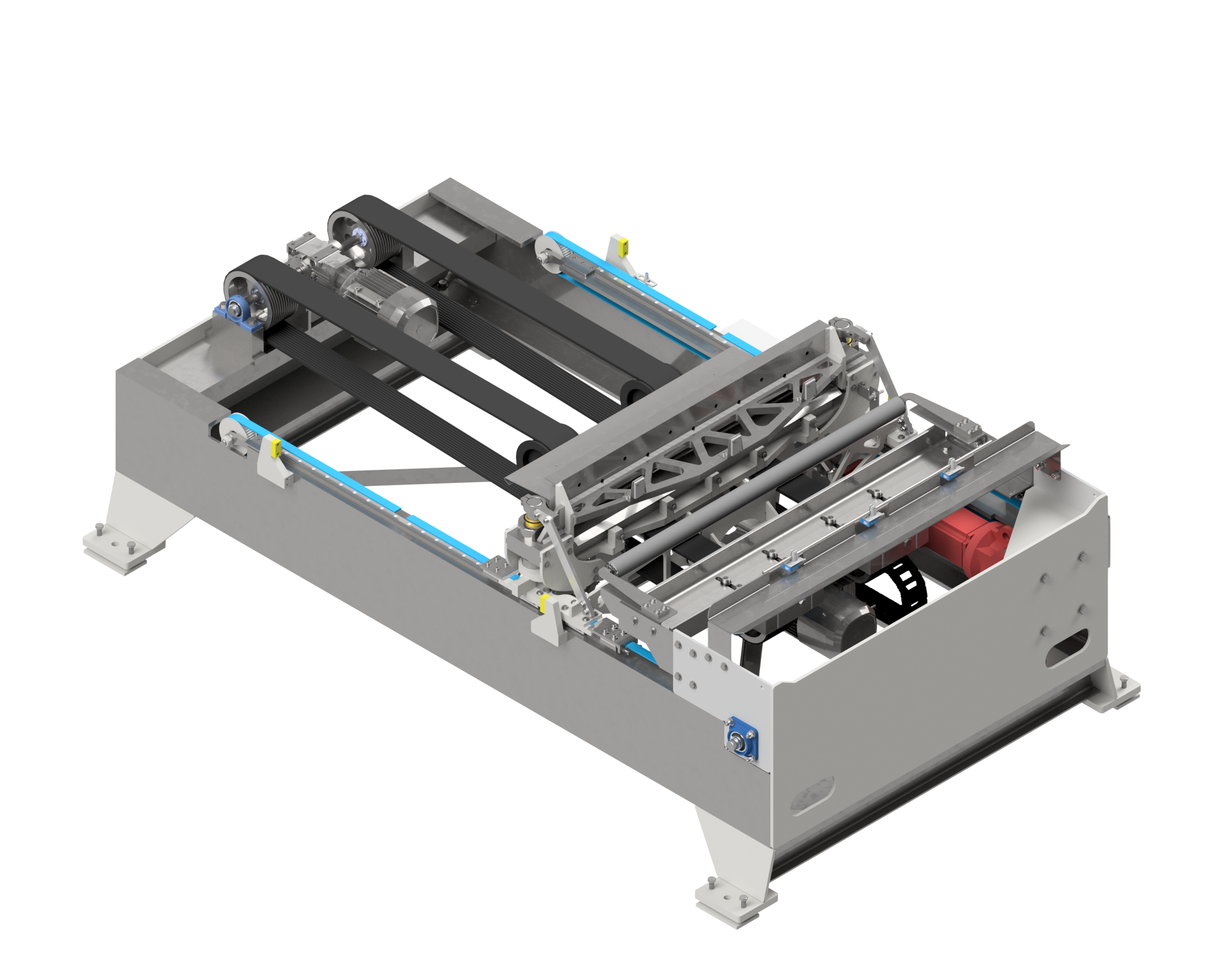

General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

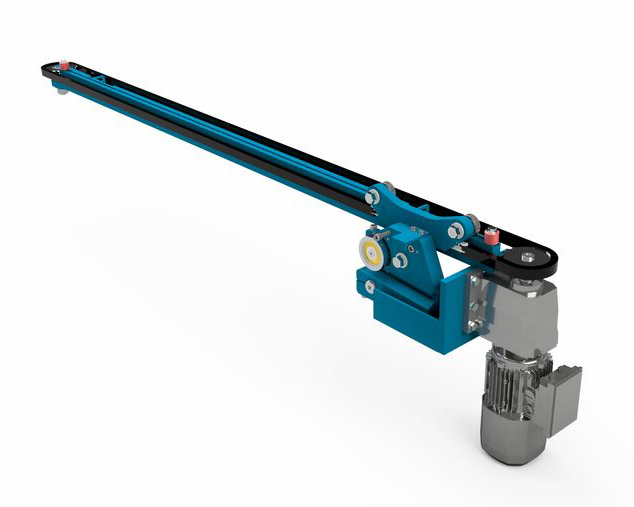

Flying Shear

The Flying Shear is an optional extra on Hayes Single Level Rollformers. It eliminates the need for the Rollformer to stop for each cut, increasing production speed. The Flying Shear is mounted on an extended chassis using a linear bearing track. A carriage supports the shear.

The Flying Shear is powered by an electric motor and linkage system. Its compact design eliminates the need for a hydraulic powerpack and is equipped with the same replaceable through-hardened D2 steel blades found on all Hayes Guillotines.

The Flying Shear is capable of a minimum sheet length of 1.8m at a 60m per/minute (200ft per/minute) line speed, which is accomplished by a servo motor/drive combination. This allows the shear to match speed with the outgoing sheet before cutting. The flying shear is mounted on an extended chassis utilizing a linear bearing track. It is supported by a carriage and powered by an electric motor and linkage system.

The Hayes Flying Shear is available only on Single Level Rollforming lines and coil widths of 940mm to 1250mm.

ENQUIRE NOW

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.