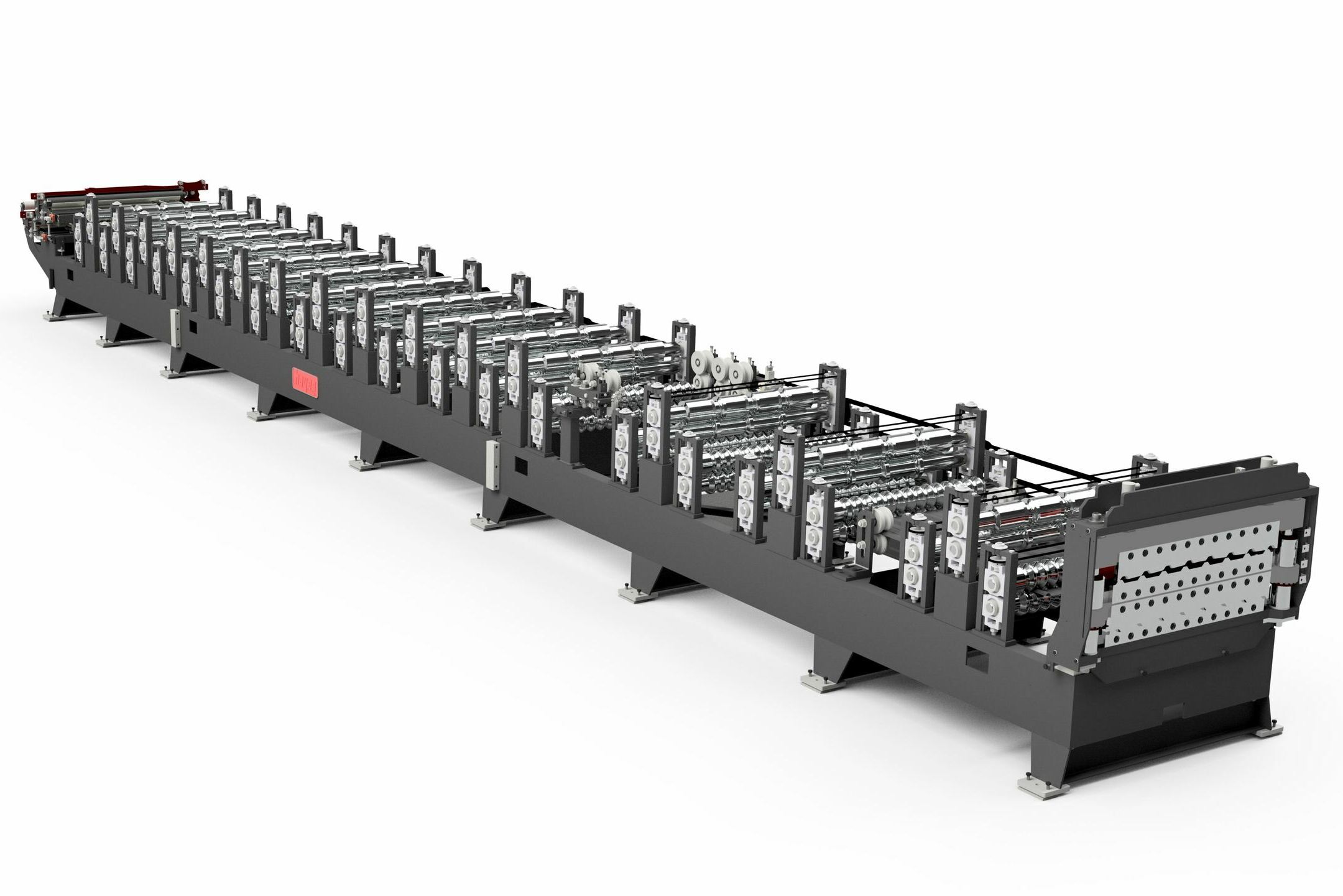

Dual Level

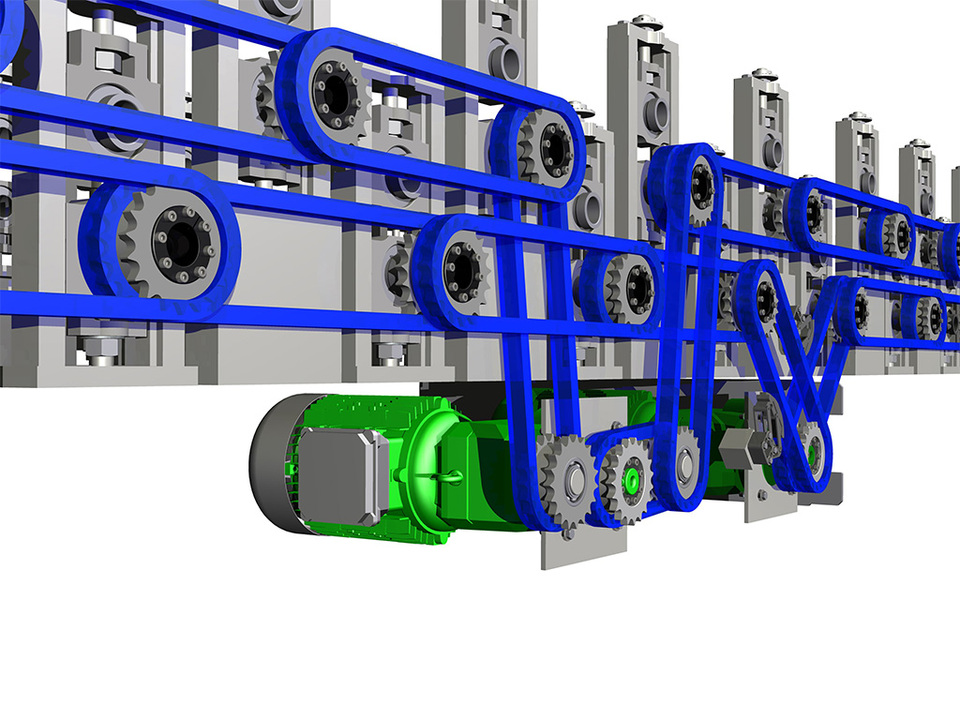

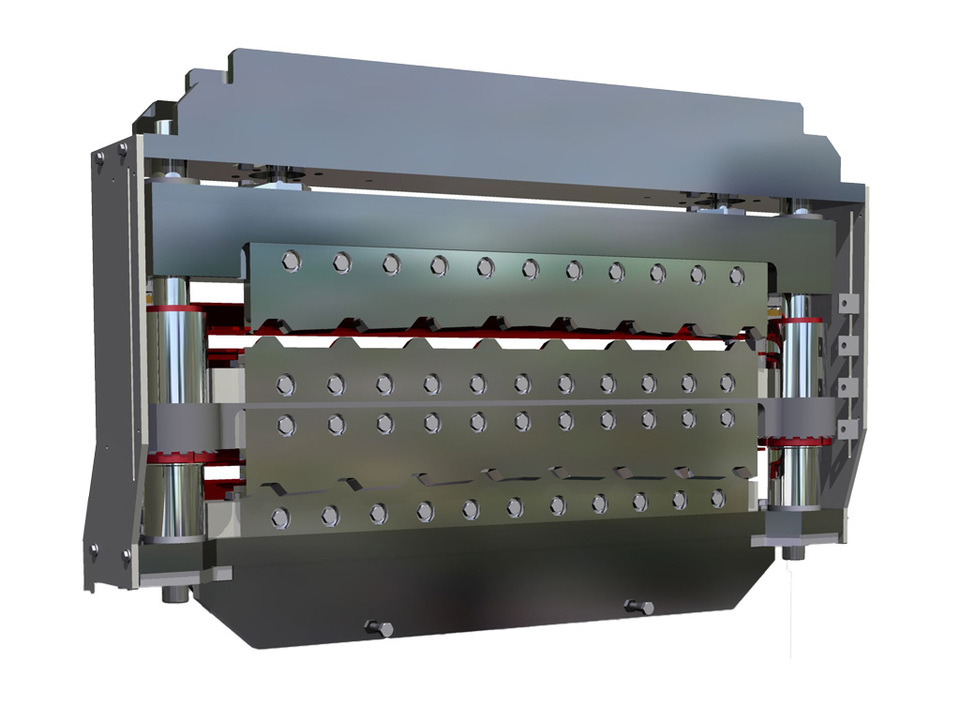

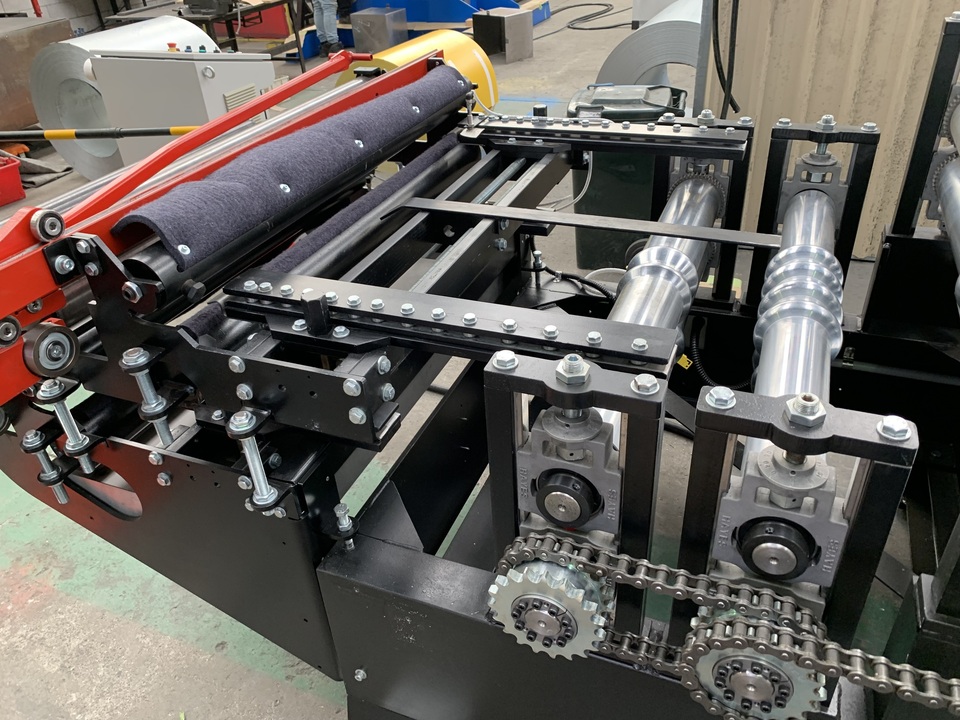

Hayes dual level Rollformers are a great option for when floor space is limited allowing for two profiles in the same basic footprint as a single level rollformer, available in a wide range of specifications that can be customized depending on your requirements. From Cladding and Decking to Roofing and Fencing lines, designed to support most industry standard coatings and coil sizes including Galvalume/Zincalume, Coloursteel, Resin coatings and more.

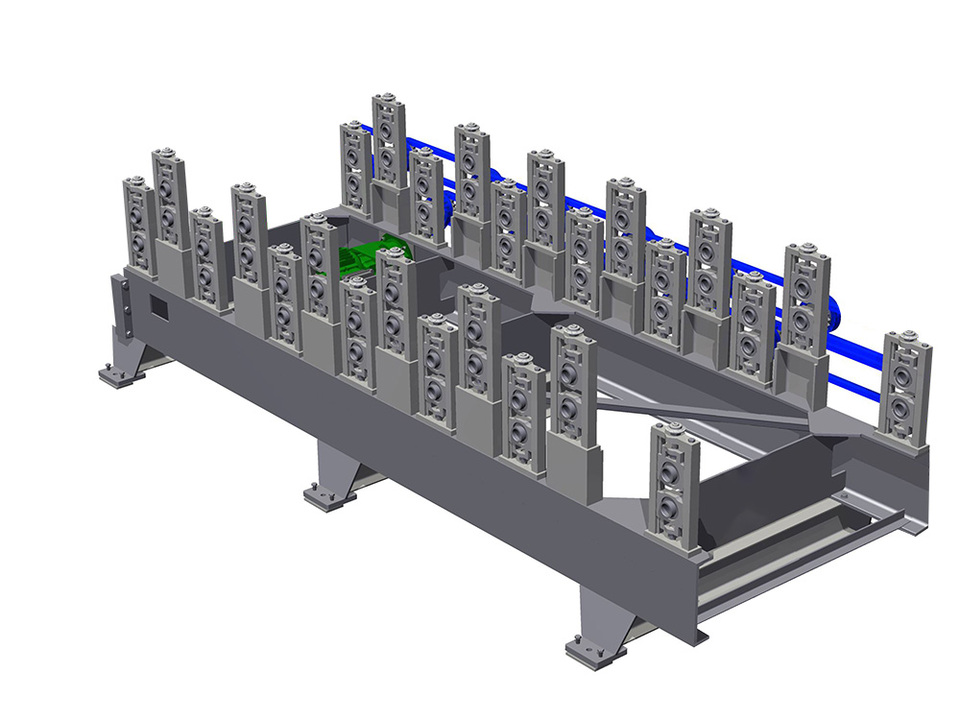

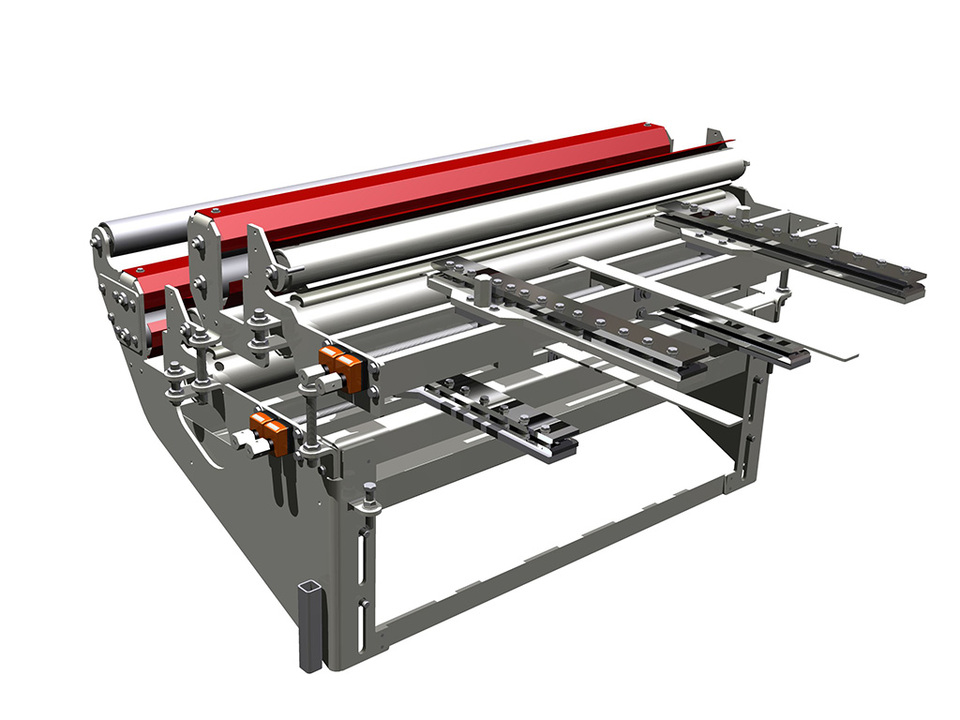

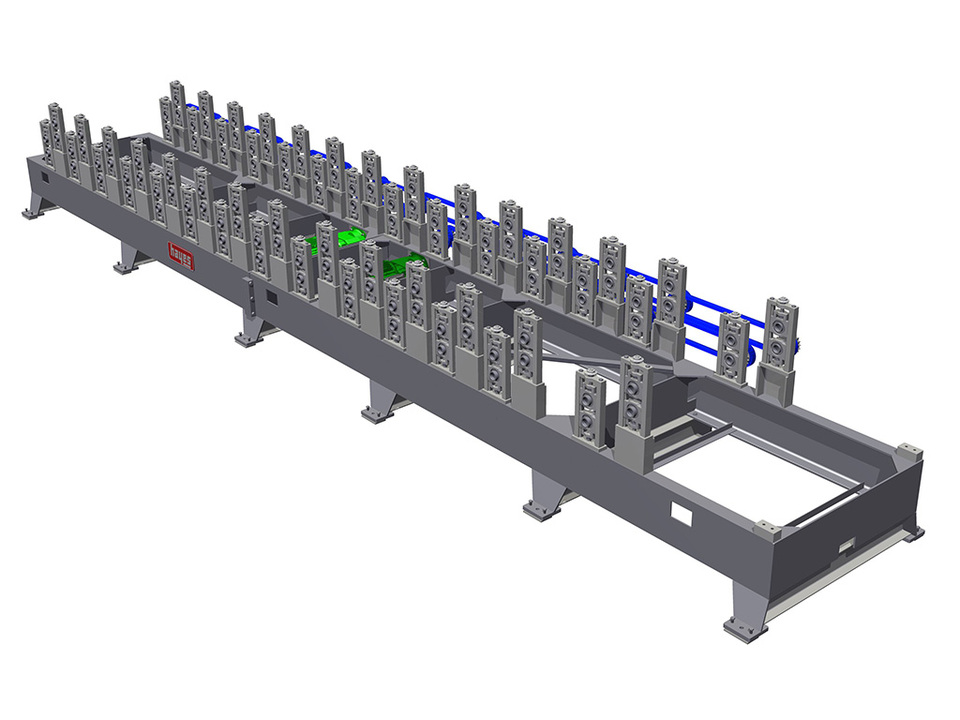

DUAL LEVEL ROLLFORMER STANDARD COMPONENTS

GALLERY

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.