Hayes

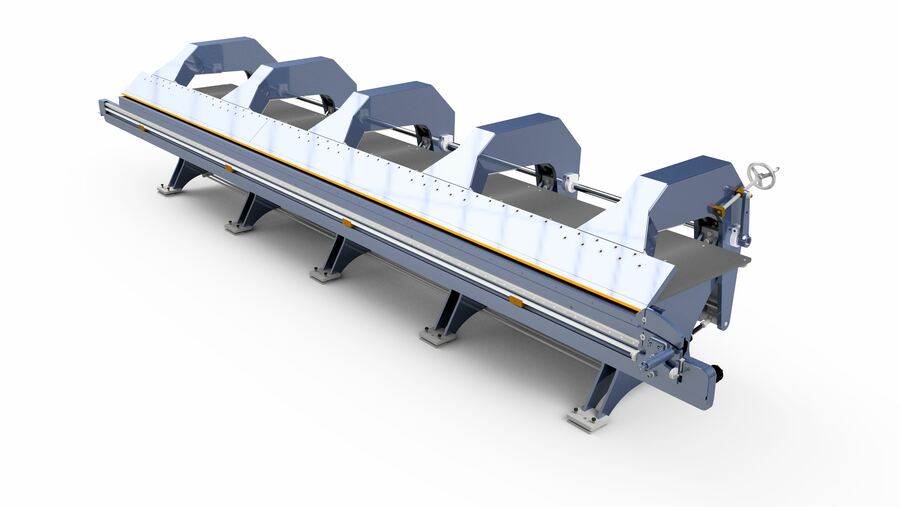

sheet metal folders are efficient and reliable way to produce folded metal

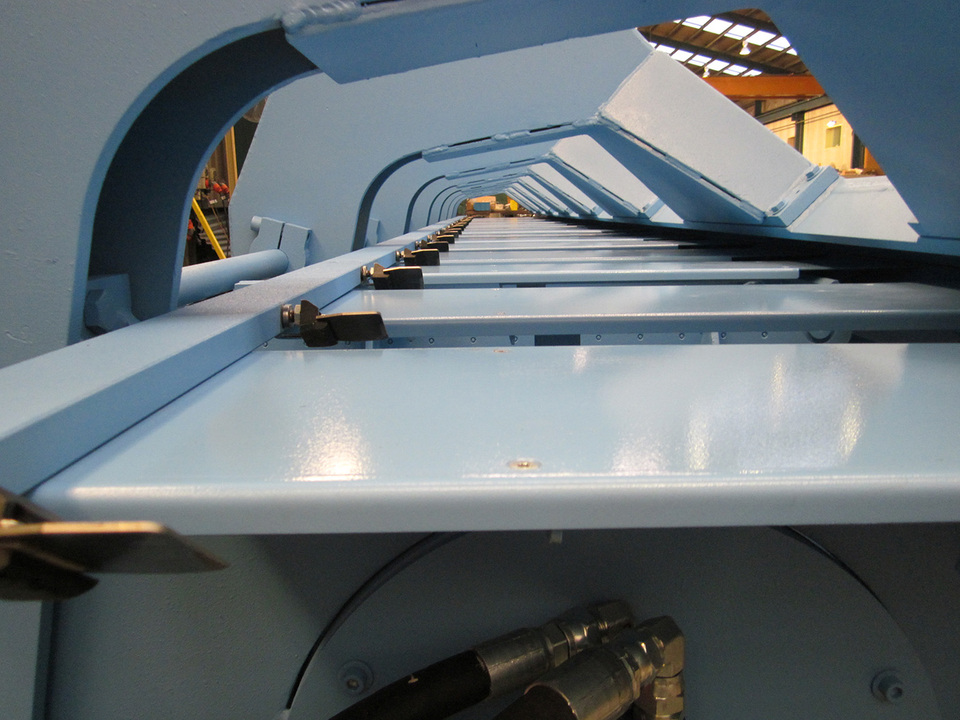

parts, Hayes Folders are a fabricated steel construction with accurately

machined working surfaces, with a full-length backbone chassis to eliminate

flexing available in 6-meter, 8-meter, and 10-meter lengths with either 16ga or

14ga capacity. An optional apron mounted slitter can be included allowing the

operator to cut products after folding when required. Hayes Folders also

feature a full-length back gauge stop with numerical control for position and

fold angle. The operator’s console is mounted to the chassis on a swiveling arm fitted with a touch screen control and fully instrumented with functions

for clamp, bend and slit. Onboard software allows for a parts library to save

and store programs for future use.

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.