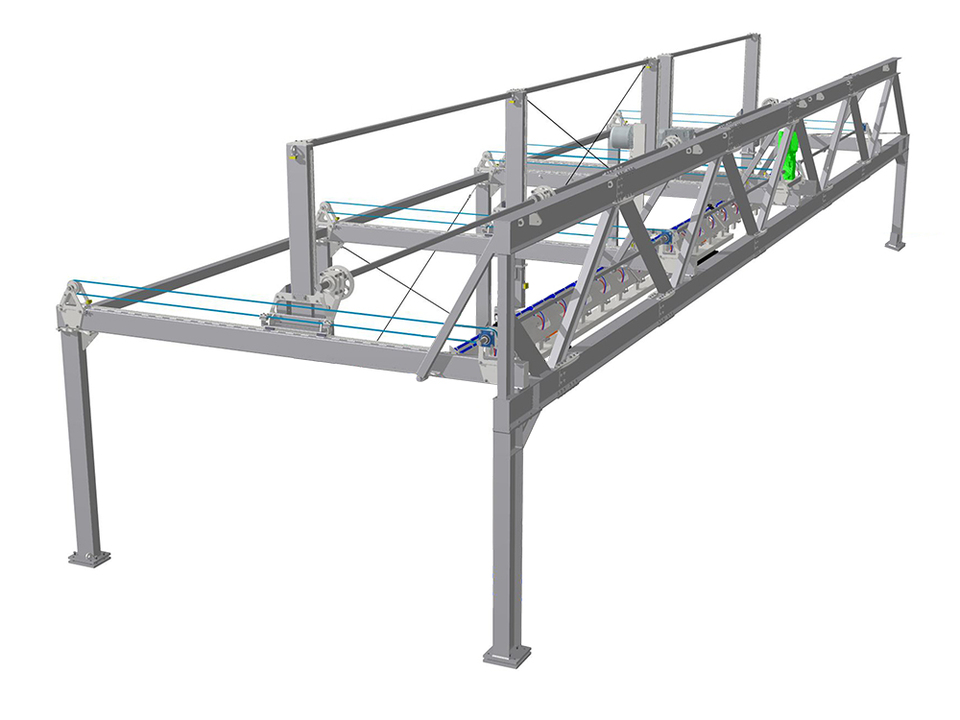

Purlin Stacker

Hayes

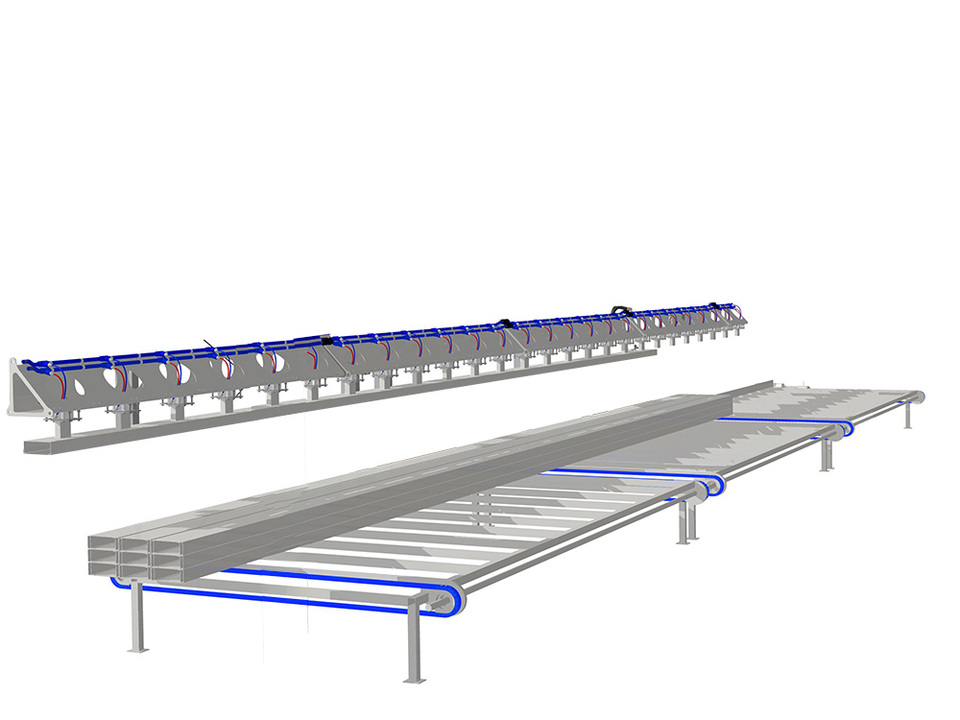

Purlin Stacker systems enable a seamless, hands-free stacking operation from

the rollformer exit. The Hayes Purlin Stacker stacks finished profiles via

mechanical push and flip / nest technology to present finished products neatly and

ready for strapping, either manual or automatic. The Hayes Purlin Stacker is fully fenced unit with

guarding around the entire perimeter and light curtains placed at the

collection side of the stacker to prevent danger to operators.

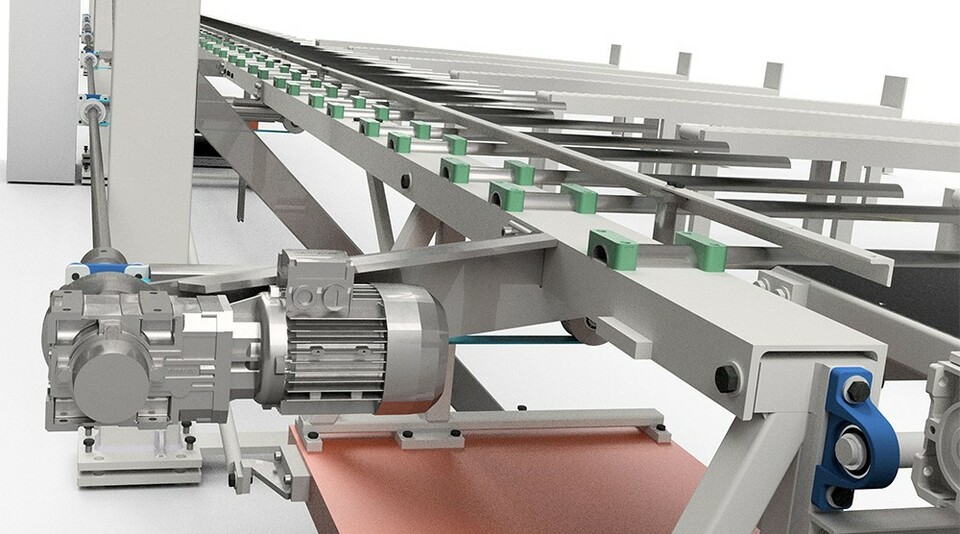

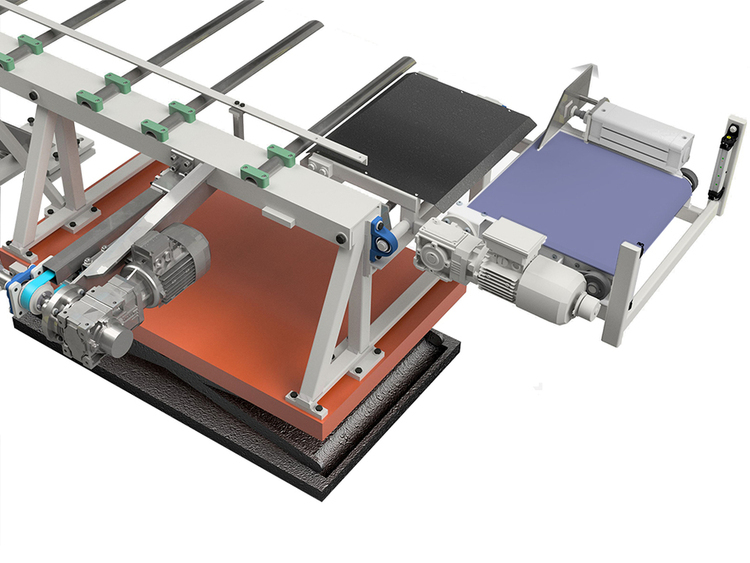

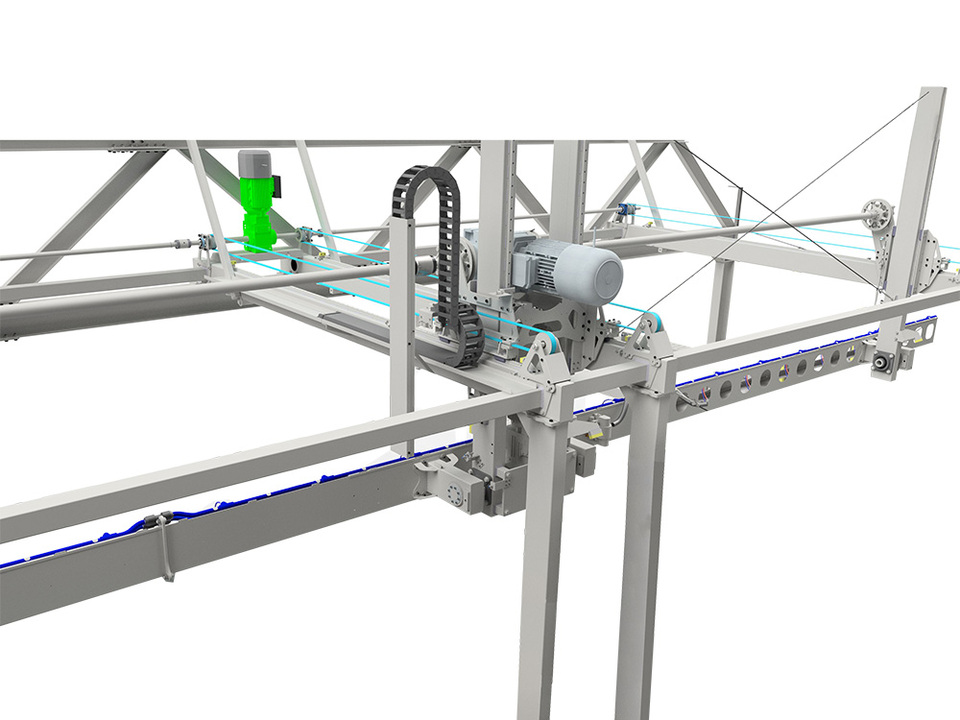

PURLIN STACKER STANDARD COMPONENTS

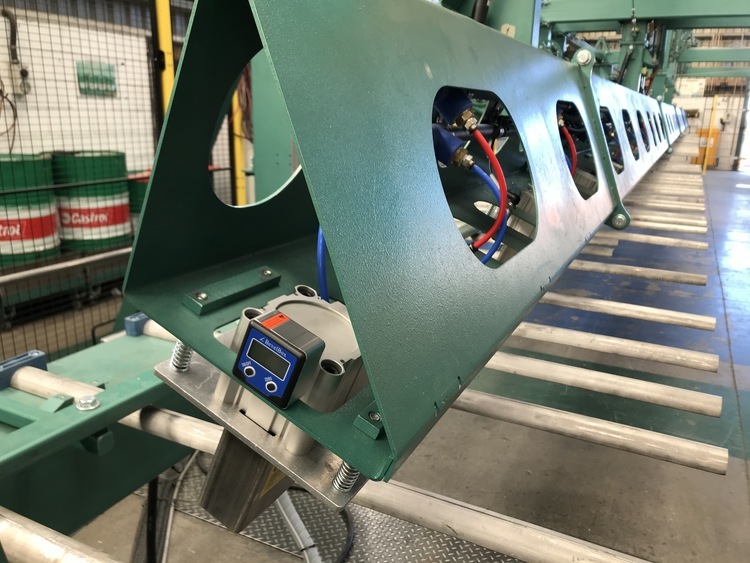

GALLERY

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.