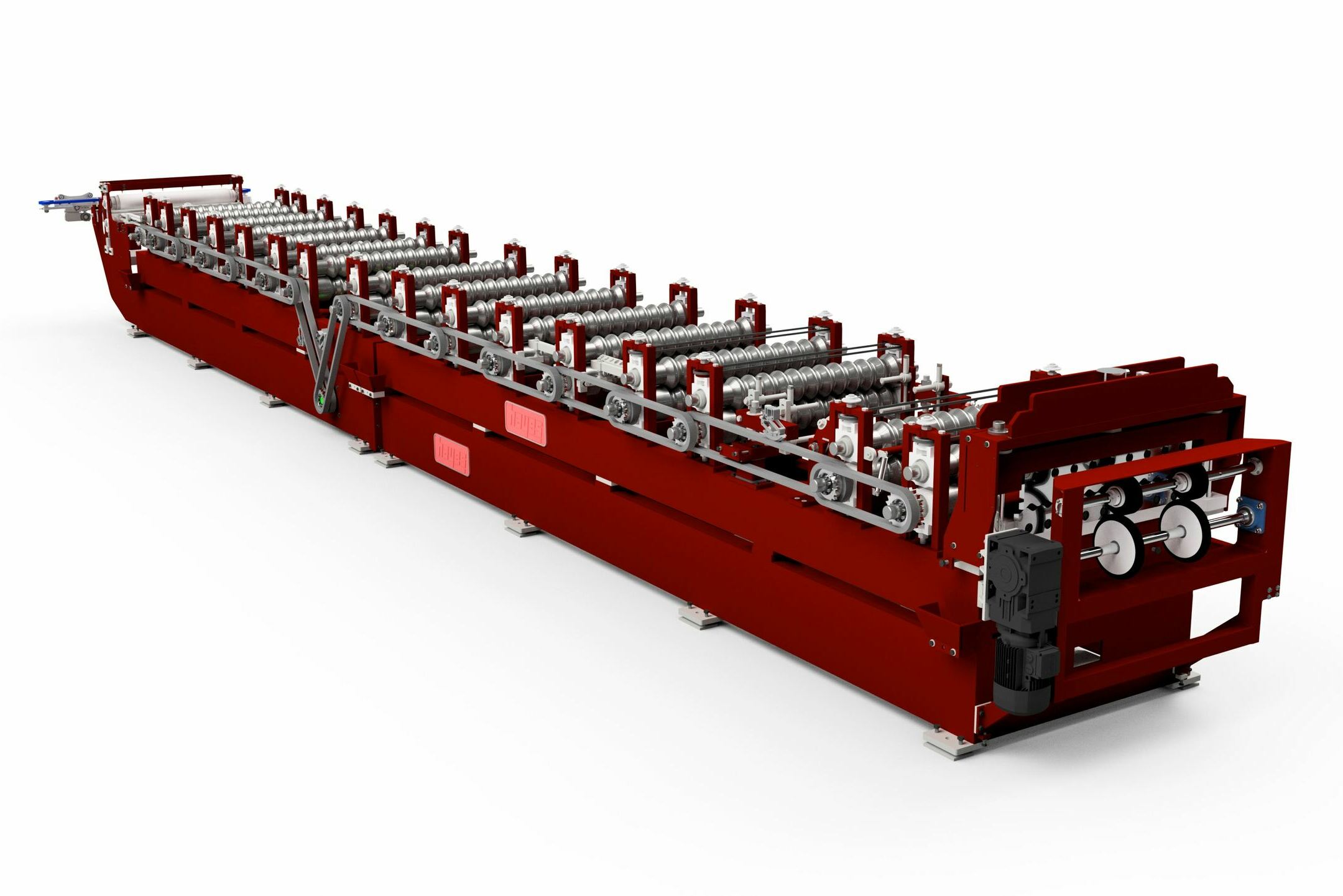

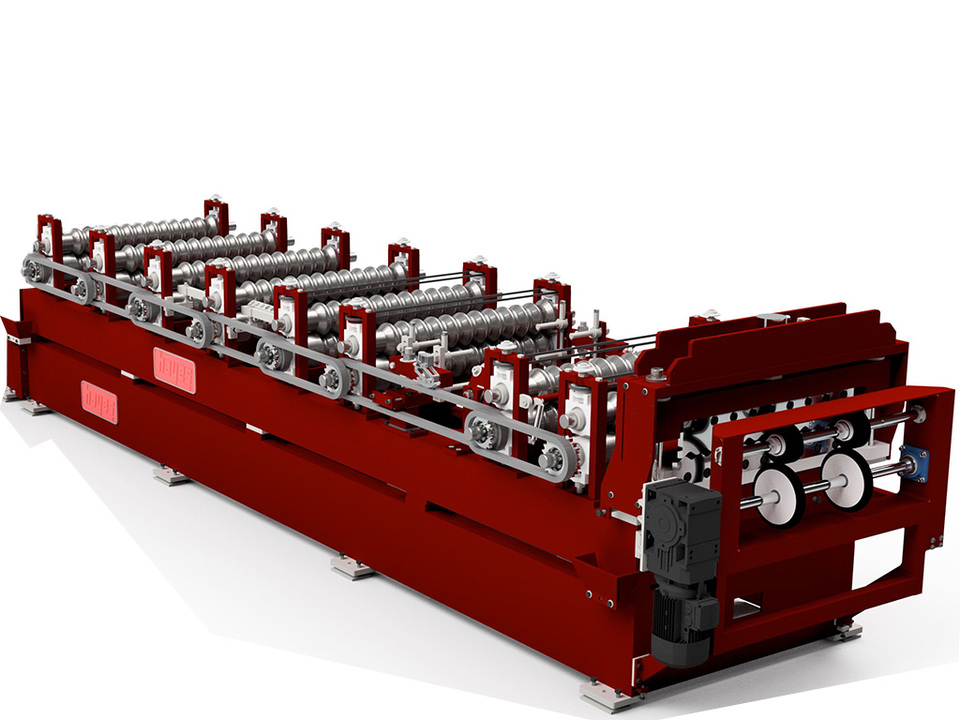

Rafted

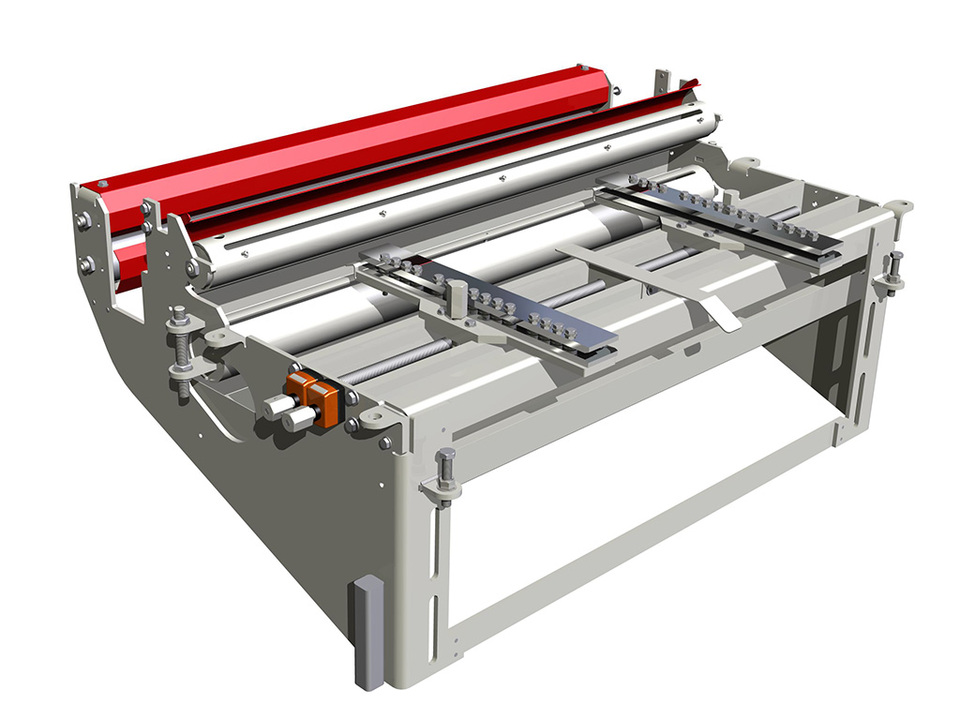

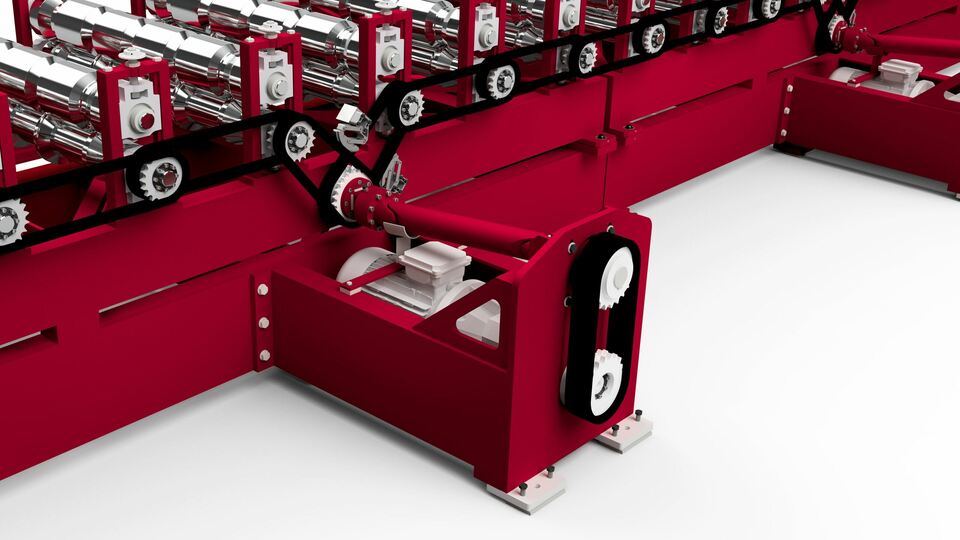

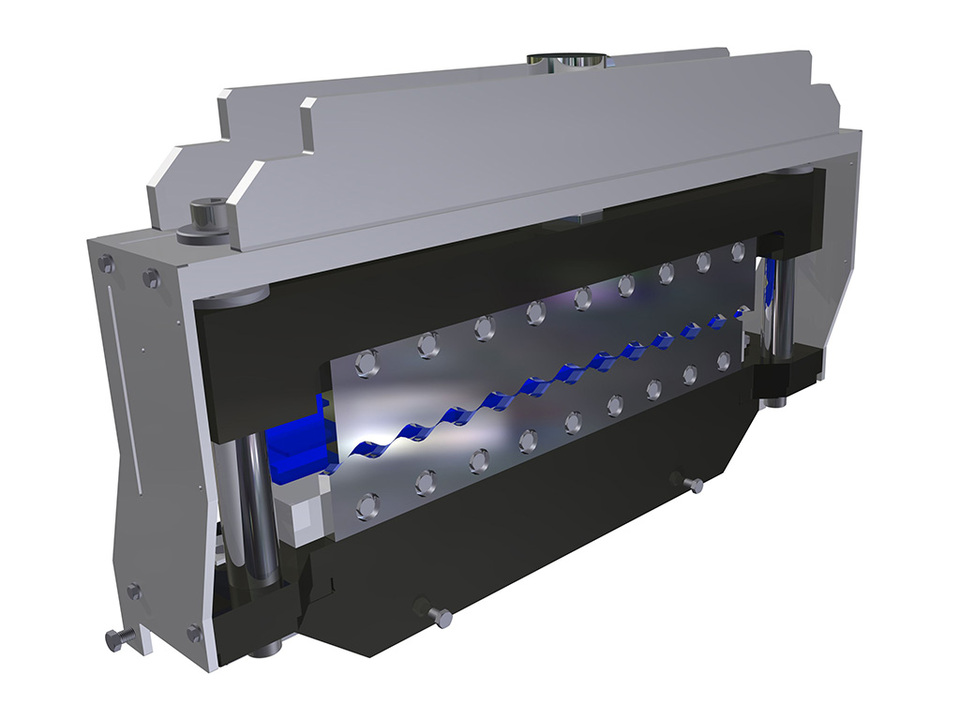

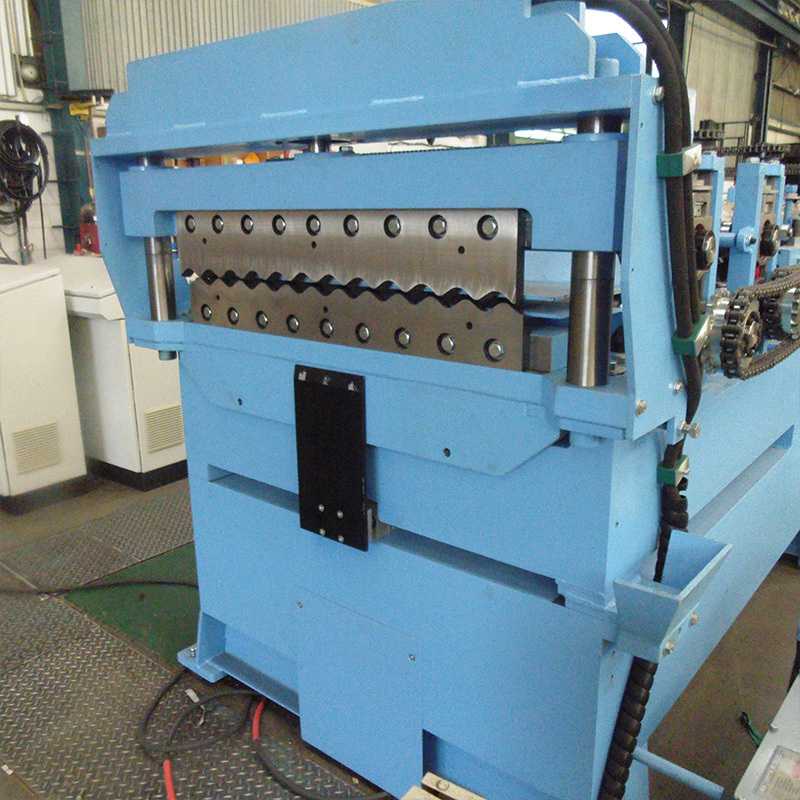

Available in dual and single level configurations Hayes Rafted rollformers are an efficient way to cater for a large range of profiles when floor space is limited. Rafted rollformers are available in much the same configuration as Hayes single, and dual level rollforming lines; designed to support most industry standard coatings and coil sizes including Galvalume/Zincalume, Coloursteel, Resin coatings and more. The Hayes Rafted Rollforming Line utilizes a common base and drive chassis unit, control system and transmission, together with demountable forming rafts each having dedicated tooling to manufacture a range of profiles according to customer specification. The drive and electrical connections to the raft are fitted with quick-release type couplings to facilitate quick changeover, the raft modules have balanced lifting points and are designed to be lifted on and off the chassis in sections.

RAFTED ROLLFORMER STANDARD COMPONENTS

GALLERY

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.